LVT flooring production line

LVT flooring production line

Discover the Polytech ME LVT Flooring Machine. Learn about luxury vinyl tile (LVT) flooring, its production process, machine features, technical specifications, and applications.

Description

What is LVT Flooring and Its Benefits

Luxury Vinyl Tile (LVT) flooring is a popular vinyl flooring option composed of multiple PVC layers. It is known for being environmentally friendly, easy to install, and highly durable. High-quality LVT includes a sturdy wear layer, making it waterproof, scratch-resistant, and longer-lasting than standard laminate flooring.

- Durability: LVT’s tough wear layer provides excellent abrasion resistance (up to 300,000 revolutions in testing), with a typical lifespan of 5–10 years.

- Elasticity: The vinyl core makes LVT slightly softer and more impact-resistant than ceramic or wood, improving comfort and resilience.

- Fire Retardant: Certified LVT floors achieve fire-resistance ratings up to class B1, self-extinguishing if ignited.

- Easy Maintenance: The smooth surface of LVT is simple to clean (usually just mopping) and requires minimal upkeep.

- Waterproof: LVT is inherently water and moisture resistant, making it ideal for kitchens, bathrooms, and basements.

- Aesthetic Variety: LVT can mimic wood, stone, or tile with high-resolution decorative films and embossing. It offers wide color and pattern options to suit any decor.

LVT Flooring Production Process

The LVT flooring production line uses a continuous extrusion process followed by lamination and finishing. Key steps include:

- Material Mixing & Extrusion: PVC resin, calcium carbonate, plasticizers, stabilizers, and additives are mixed in a high-speed mixer. The blend is fed into a twin-screw extruder which plasticizes and extrudes a vinyl sheet.

- Calendaring: The molten PVC sheet passes through a multi-roll calender, precisely adjusting the thickness and smoothing the surface.

- Lamination: Decorative printed film (for design) and a clear wear layer (for protection) are applied and laminated onto the base PVC sheet under heat and pressure.

- Cooling and Cutting: The laminated LVT sheet is then cooled (often in a water bath) to solidify and stabilize the material. Finally, the sheet is cut to the desired length and either stored or sent for further processing (like profile cutting or slitting).

This process creates a finished LVT plank or tile with bonded layers. Polytech’s LVT line is designed for continuous, uniform production, ensuring each layer is consistently applied and cured.

Key Features and Functions of the LVT Flooring Machine

Polytech’s LVT Flooring Machine incorporates several specialized components to ensure high-quality production:

- Conical Twin-Screw Extruder: A heavy-duty twin-screw extruder (e.g. SJZS series) provides thorough mixing of PVC and fillers. The conical design ensures uniform pressure and melting for a homogeneous material.

- Multi-Roll Calendaring: Three or four adjustable roll calendars precisely set the sheet thickness and surface finish.

- In-Line Lamination Unit: A station for one-step lamination applies the decorative PVC film and transparent wear layer to the extruded sheet while it is hot.

- High-Precision Die: The T-die (shaping die) is engineered for uniform material flow, ensuring consistent width and edge quality.

- Cooling Bath: After lamination, the flooring passes through a cooling (water spray) tank that quickly brings the PVC to stable dimensions.

- Cutting and Stacking: Automated cutters cut the continuous sheet into planks or tiles of specified length, and conveyors or stacking tables organize the output.

- PLC Control System: The entire line is controlled by a PLC (Programmable Logic Controller) with touchscreen interface, allowing precise speed and temperature control for optimal performance.

Together, these features allow the LVT line to produce high-volume, consistent flooring panels. The process is largely continuous and automated, minimizing downtime and human error.

Advantages of Polytech’s LVT Flooring Machine

Polytech’s LVT lines offer several key advantages over conventional flooring production:

- High Output: The twin-screw extrusion system enables a continuous, high-speed process. Advanced mixing and conveying increase throughput compared to single-screw lines.

- Process Efficiency: Automated control of speed, temperature, and lamination yields consistent product quality. Better mixing and controlled heating reduce material waste and energy consumption.

- Durable Construction: Built with robust steels and precise tooling, the machines ensure long service life and stable operation. Regular maintenance is easy thanks to modular design.

- Versatility: The line can be configured for different LVT products (various thicknesses or added underlays). Multi-function designs allow switching between single-layer or multi-layer production.

- Ease of Operation: User-friendly HMI (touchscreen) and one-key start-up features reduce labor needs. Diagnostic systems and quick-change components minimize downtime.

- Environmental Benefits: Efficient melting and excess material reprocessing help reduce energy use and scrap. LVT production itself emits no formaldehyde, aligning with green manufacturing.

Overall, Polytech’s LVT Flooring Machines deliver high performance and reliability, producing large volumes of high-quality LVT flooring while lowering production costs and energy usage.

Products

Applications of LVT Flooring

LVT flooring is extremely versatile and used in many settings:

- Residential: Ideal for homes (living rooms, bedrooms, kitchens) due to comfort underfoot, warm appearance, and ease of installation. Its water resistance makes it suitable for bathrooms and kitchens.

- Commercial: Common in retail stores, hotels, restaurants, and offices where style and durability are both important. LVT’s design variety and wear resistance make it a favorite for showrooms and hospitality.

- Industrial: Suitable for light industrial or institutional areas like hospitals, schools, and warehouses where a tough, hygienic floor is needed. Its impermeable surface is easy to clean and maintains performance under heavy foot or trolley traffic.

- Others: LVT is also used in healthcare (clinics, hospitals), education (classrooms, gyms), and public buildings for its hygienic and low-maintenance qualities.

These applications leverage LVT’s strength, stability, and aesthetic flexibility. Unlike natural wood or ceramic, LVT can combine realistic textures with practical benefits like sound insulation and easy care.

Applications

Gallery

Main Features

Technical Specifications

The table below compares technical specifications for three common LVT line models, featuring SJZS series twin-screw extruders:

| Model | Screw Diameter (mm) | T-Die Width (mm) | Thickness Range (mm) | Output (ton/24h) | Main Motor (kW) |

|---|---|---|---|---|---|

| SJZS-80/156 | 80 / 156 (conical) | 1050 / 1350 | 1–3 | 6–10 | 55 |

| SJZS-92/188 | 92 / 188 | 1050 / 1350 | 1–3 | 15 | 110 |

| SJZS-110/220 | 110 / 220 | 1050 / 1350 | 1–3 | 30–40 | 200 |

Specifications like width, thickness, capacity, and motor power are based on typical setups. Output is given in metric tons per 24 hours of continuous operation. Higher or lower speeds can be configured for specific requirements.

Related products

-

Full Extrusion Lines

WPC/SPC Wall Panel Production Line

-

Full Extrusion Lines

POE Polymer Spinneret Pad Production Line

-

Full Extrusion Lines

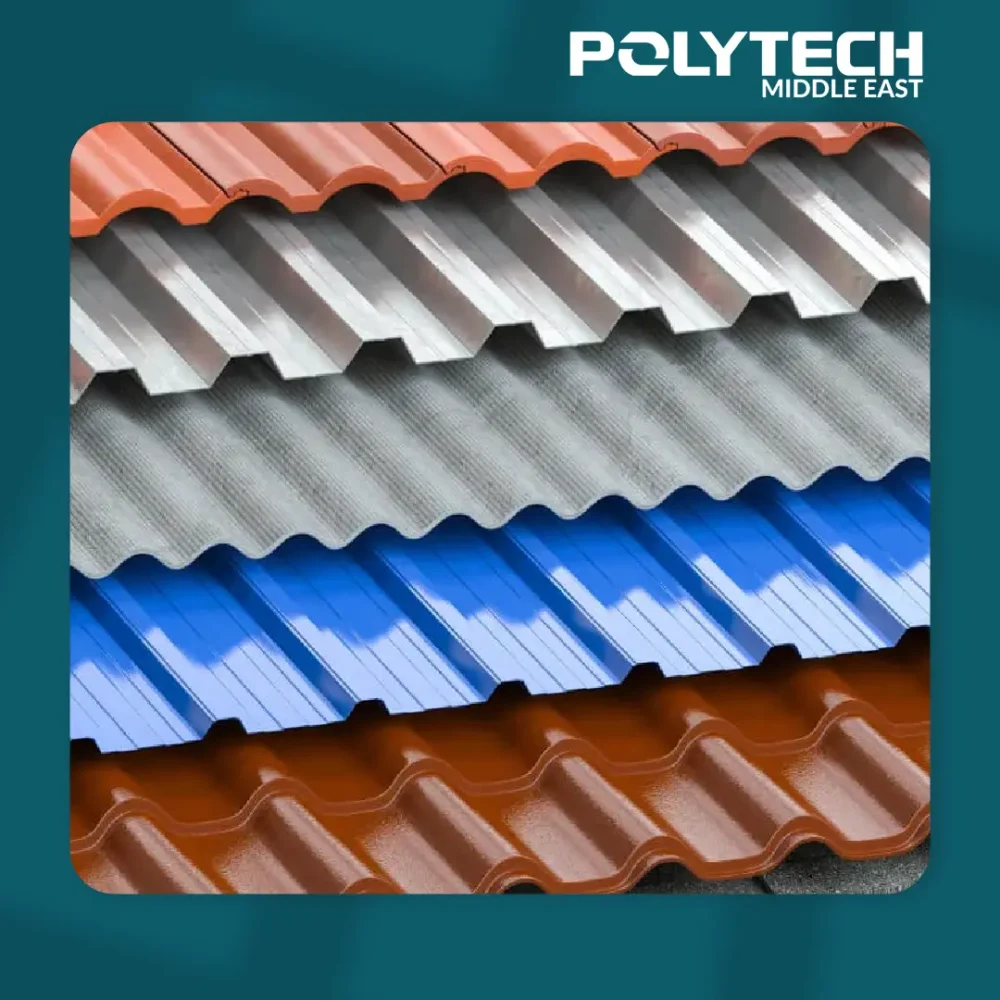

PVC Roofing Sheet Extrusion Line

-

Full Extrusion Lines

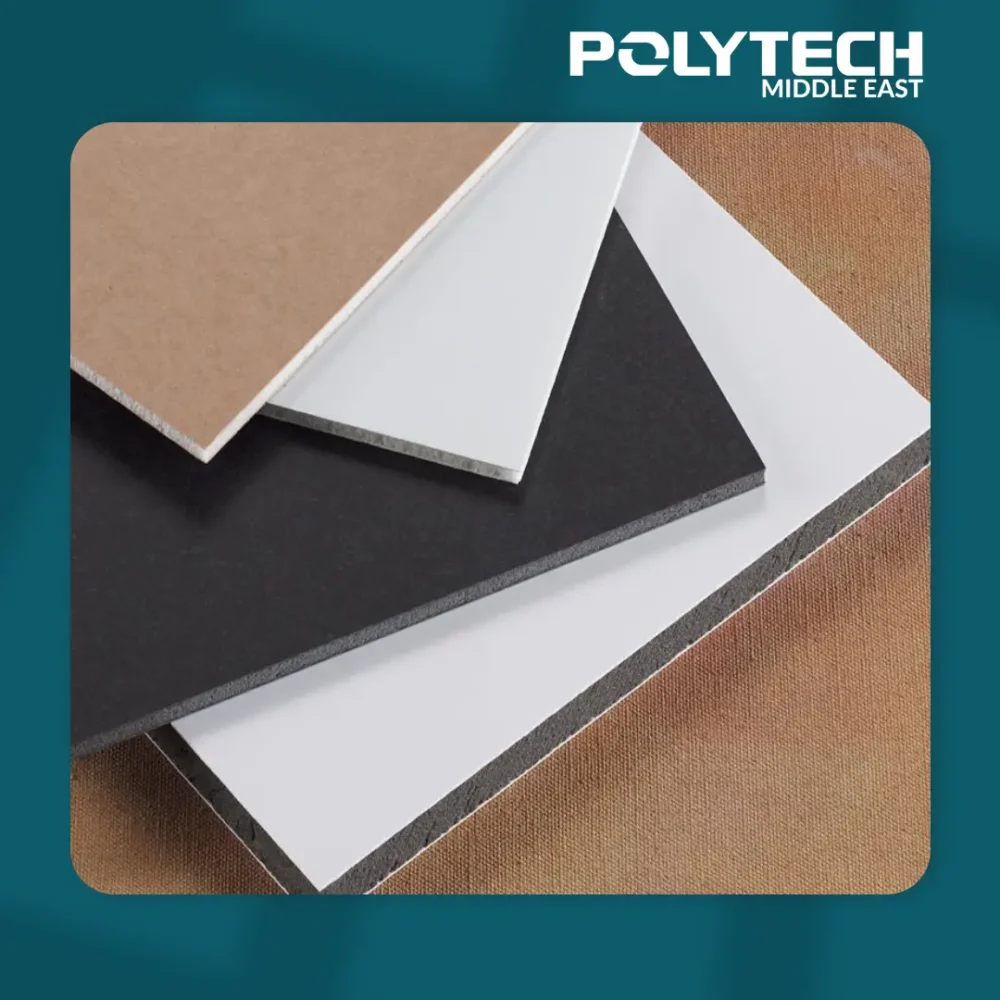

WPC Foam Board Extrusion Line