Plastic Formwork Extrusion Line

Explore advanced Plastic Formwork Extrusion Lines and Production Lines for durable, reusable formwork panels. Precision equipment for modern construction projects.

Category -> Full Extrusion Lines

Explore advanced Plastic Formwork Extrusion Lines and Production Lines for durable, reusable formwork panels. Precision equipment for modern construction projects.

Plastic Formwork Extrusion Line efficiently produces durable and lightweight plastic panels used as temporary molds in construction. By utilizing precise temperature control and specialized molds, it creates high-quality formwork that is reusable, reduces waste, and offers design flexibility. With quick cycle times, this machine enhances production efficiency and can lead to improved surface finishes and lower labor costs in various construction projects.

Due to its excellent water resistance and non-adhesive properties with cement, this construction material allows for easy demolding and enhances efficiency with smooth surfaces that need no modifications. Lightweight and durable, it can be reprocessed for sustainability and provides good insulation, helping to reduce construction times.

These features are particularly beneficial in various applications of Plastic Formwork Making Machines, including:

These applications leverage the machine’s efficiency and the advantages of plastic formwork in various construction scenarios.

Plastic Formwork Extrusion Line is a type of equipment used to produce plastic formwork panels used in construction projects. These panels are designed to form the molds or structures needed to pour concrete, providing support and shaping during the construction of walls, floors, and other concrete structures.

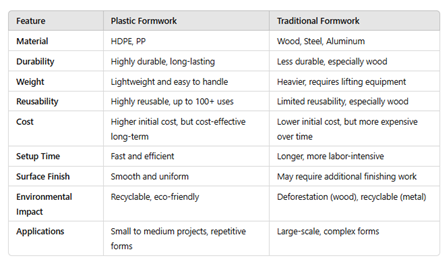

Plastic Formwork Production Line is a fully automated system designed for the mass production of plastic formwork panels, which are essential components in construction projects for shaping and supporting poured concrete. These panels are made from durable plastic materials like high-density polyethylene (HDPE) or polypropylene (PP), providing a lightweight, reusable alternative to traditional wood or metal formwork.

Reusable plastic formwork panels are increasingly popular in construction due to their durability, lightweight nature, and cost-effectiveness. These panels are made from materials like high-density polyethylene (HDPE) or polypropylene (PP) and are designed to be used multiple times, offering several advantages over traditional formwork options like wood or metal.

Plastic formwork panel extrusion process involves transforming raw plastic materials, such as HDPE or PP, into durable, reusable panels used in construction. The process includes:

Customizing a plastic formwork production line is essential for ensuring that the manufacturing process meets specific construction requirements, product quality standards, and efficiency goals.

| 915mmx1830mm | 15mm | 12kg |

| 915mmx1830mm | 14mm | 10kg |

| 915mmx1830mm | 18mm | 13kg |

| 1220mmx2440mm | 14mm | 18kg |

| 1220mmx2440mm | 15mm | 20kg |

| 1220mmx2440mm | 18mm | 25kg |