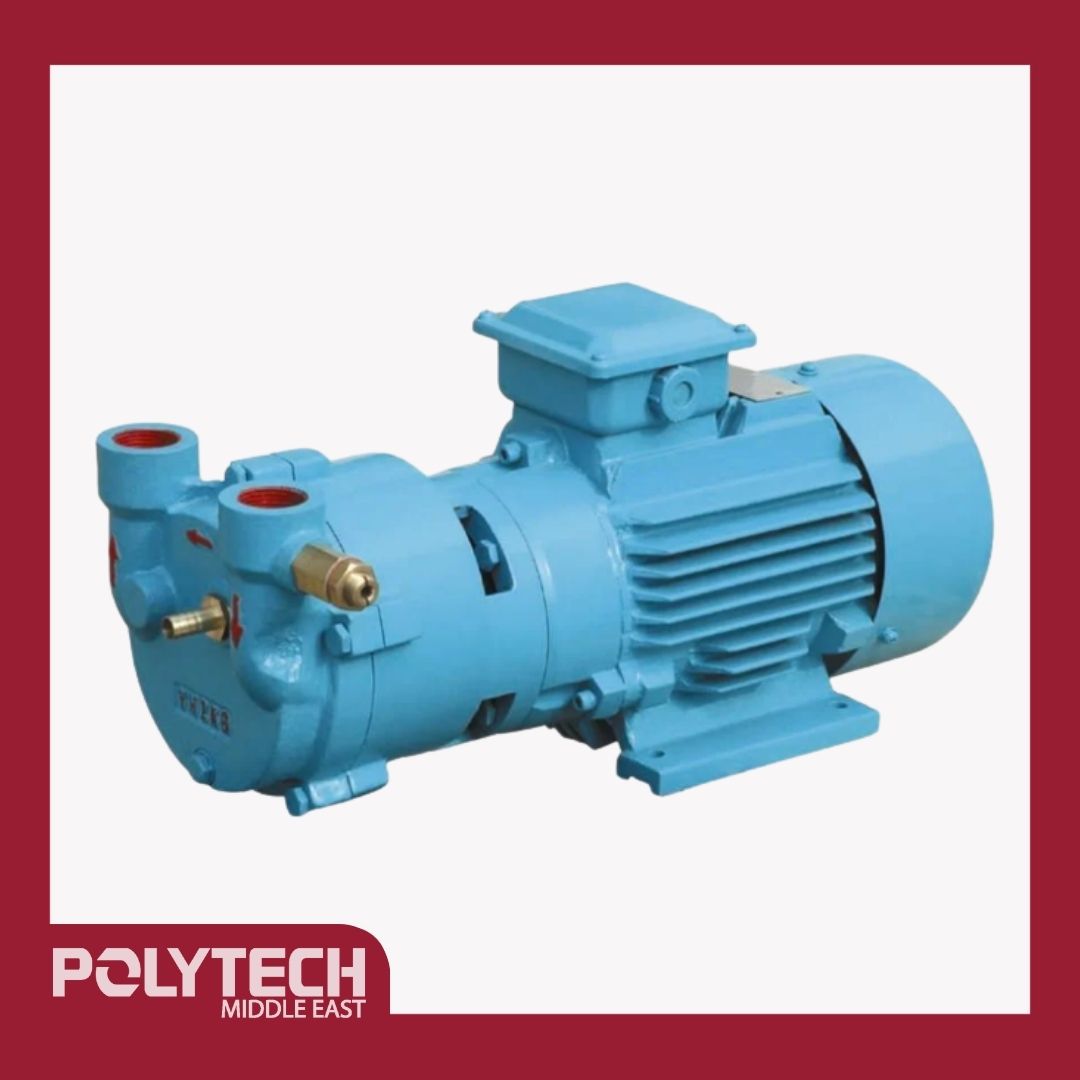

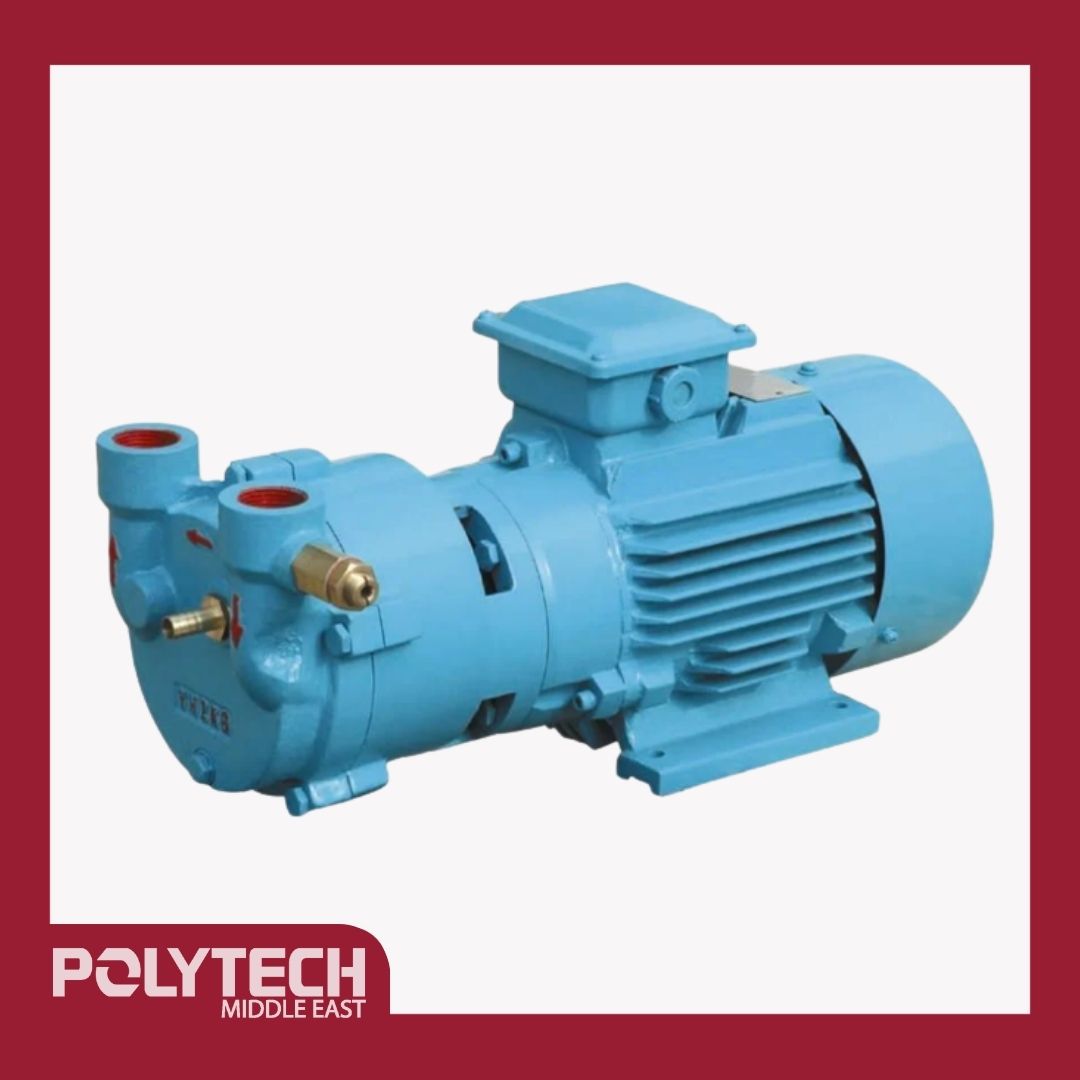

Vacuum Pumps

Discover high-performance Industrial Vacuum Pumps and systems for manufacturing. Reliable solutions ensuring precision, efficiency, and durability in industrial processes.

Category -> Machines and Spare Parts

Discover high-performance Industrial Vacuum Pumps and systems for manufacturing. Reliable solutions ensuring precision, efficiency, and durability in industrial processes.

Vacuum Pumps are an essential component for plastic extrusion lines, designed to efficiently remove air and gasses from the system. With a powerful motor, it ensures optimal vacuum levels, enhancing the quality and consistency of extruded products. This pump is compact, energy-efficient, and built for durability, making it ideal for continuous operation in demanding industrial environments. Its reliable performance helps prevent defects in the extrusion process, ensuring smooth production and high-quality output.