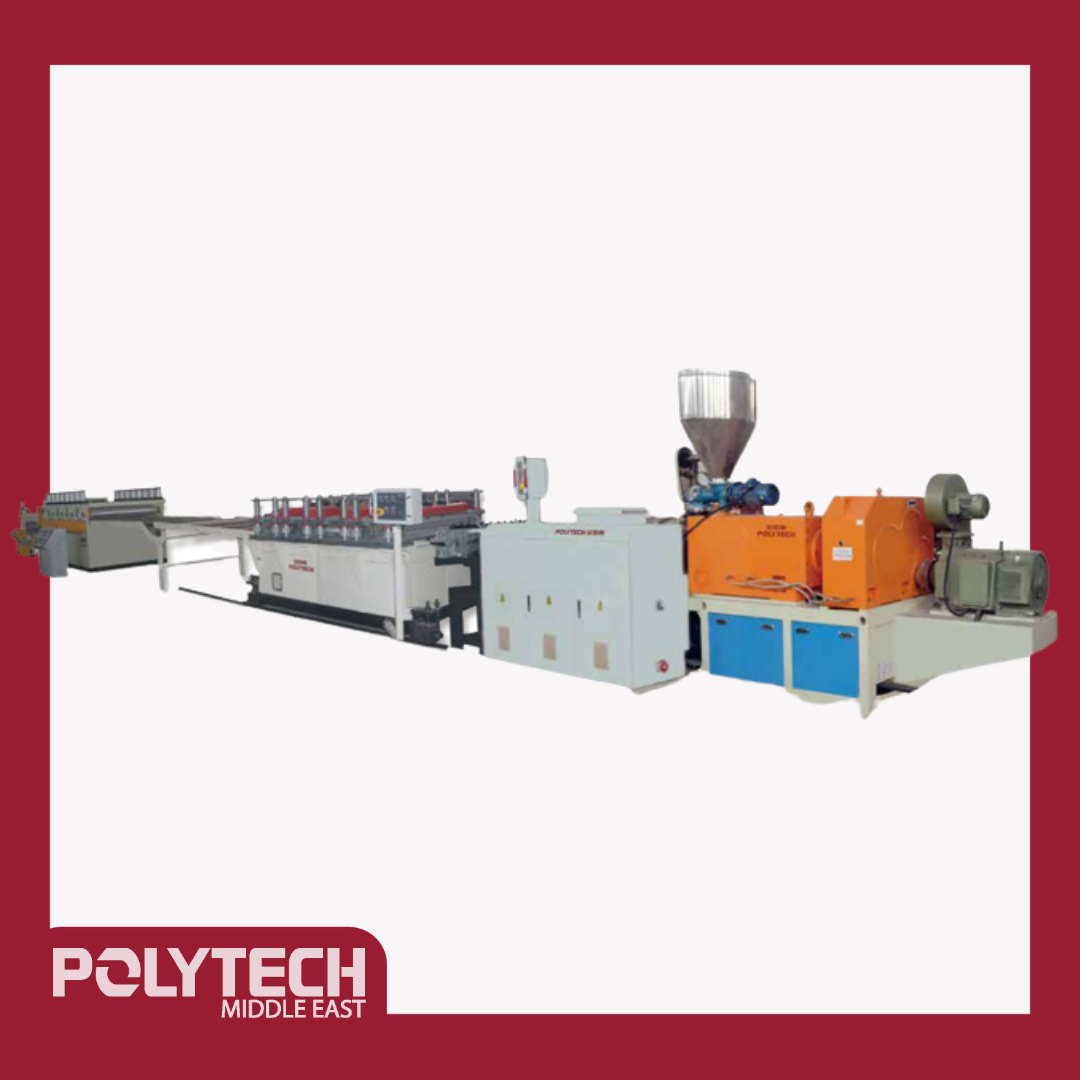

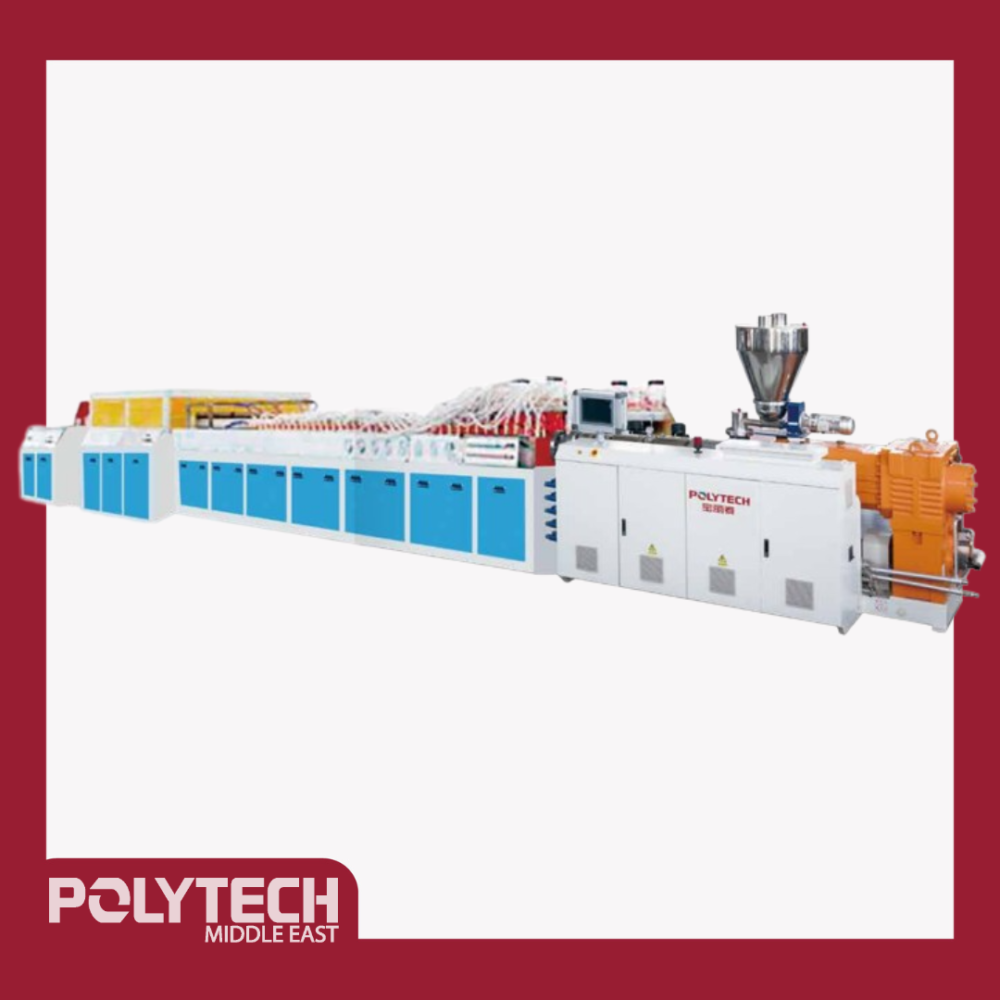

A PVC Advertising Foam Sheet Machine produces lightweight, durable foam sheets from polyvinyl chloride (PVC). Ideal for signage and advertising, it efficiently extrudes and shapes PVC for various sizes and thicknesses, offering excellent printability and moisture resistance.

PVC Advertising Foam Sheet Machine Features and Application:

Due to its superior hydrophobic properties and non-adhesive characteristics with cement, this construction material enables efficient demolding and enhances operational efficiency through its smooth surface, eliminating the need for additional finishing processes. It exhibits effective sound and thermal insulation, along with moisture resistance and shock absorption capabilities. The material can be easily manipulated—drilled, sawed, nailed, or adhered—facilitating straightforward transportation and assembly. These technical properties render it suitable for a variety of applications, including cabinetry, sanitary installations, high-end furniture manufacturing, decorative building materials, signage, and interior finishing in automotive, rail, and marine contexts.

Technical specifications:

| Foam board type | Free Foam Board | Calibrated foamed board | ABA foamed sheet |

| Model | SJZS80/SJZS92 SJZS80/92TWIN SCREW EXTRUDER | SJZS80

/SJZS92 SJZS80/92TWIN SCREW EXTRUDER |

SJZS80

/SJZS92 SJZS80/92TWIN SCREW EXTRUDER |

| Main motor power | 75kw/110kw | 75kw/110kw | 75kw+37kw/110kw+37kw |

| Specification Can be produced depend on customer’s requirements | width:915/1220/1830mm Thickness:3-25mm/25-50mm | ||

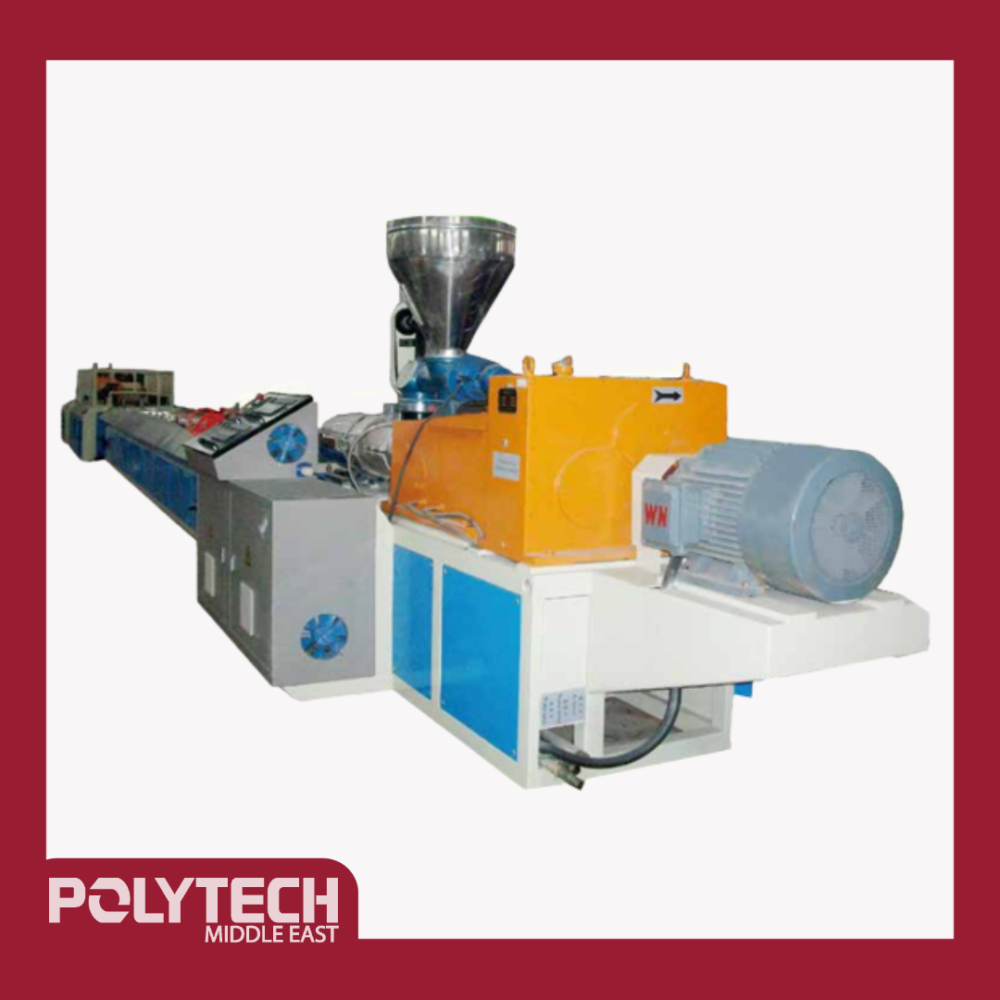

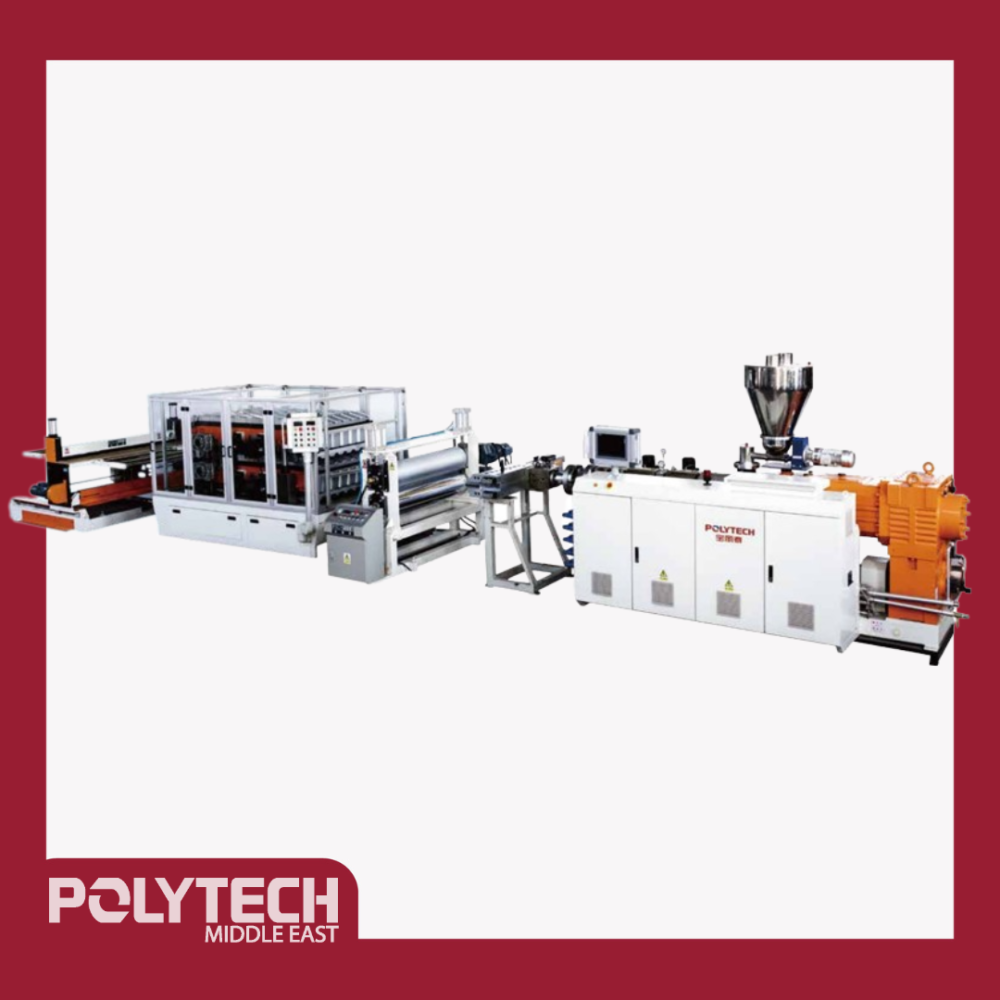

What is a PVC Foam Sheet Machine?

PVC foam sheet machine is a specialized piece of equipment used to produce PVC foam sheets. These sheets are lightweight, durable, and versatile, with a variety of applications in construction, advertising, signage, and furniture. The machine utilizes an extrusion process to create a foam structure within the PVC material, giving the sheets their unique properties such as high strength-to-weight ratio, moisture resistance, and ease of handling.

Plastic Foam Sheet Machine Features

Plastic foam sheet machines are designed to produce various types of foam sheets, such as PVC foam, PS foam, and PE foam, which are used across a wide range of industries. These machines are equipped with advanced features to ensure high-quality, efficient production of foam sheets with customizable properties like density, thickness, and surface texture.

Applications of PVC Foam Boards

- Signage and Advertising: Used for outdoor signs, billboards, and retail signage.

- Construction: Ideal for wall cladding, partitions, and ceiling panels due to their durability and moisture resistance.

- Furniture Manufacturing: Used in cabinets, doors, and storage solutions.

- Interior Design: Employed for decorative panels, 3D wall art, and false ceilings.

- Packaging: Used for protective packaging and custom boxes.

- Print and Graphics: Suitable for digital printing and creating photo frames.

- Marine and Outdoor: Used in boat interiors and weather-resistant furniture.

- DIY and Craft Projects: Popular in model making and school projects.

PVC Foam Board Manufacturing Process

- Raw Material Preparation: PVC resin, foaming agents, and additives are mixed to form a homogeneous compound.

- Mixing: The raw materials are blended to ensure even distribution of the foaming agent and additives.

- Extrusion: The mixture is fed into an extruder, where it’s melted and shaped into a sheet with a foamed structure.

- Calibration and Cooling: The foam sheet is flattened to the desired thickness and cooled to solidify.

- Cutting: The cooled board is cut into standard or custom sizes.

- Surface Treatment (optional): Some boards undergo surface texturing or lamination for enhanced appearance and durability.

- Quality Control: The boards are inspected and tested for defects and consistency.

- Packaging: Finished boards are packaged for shipment, often wrapped in protective film.

Benefits of Using PVC Foam Sheet Machines

Advantages include lightweight materials, cost-effective production, and durability for multiple industries.

Reviews

There are no reviews yet.