Plastic Flake Pelletizing Line

Plastic Flake Pelletizing Line

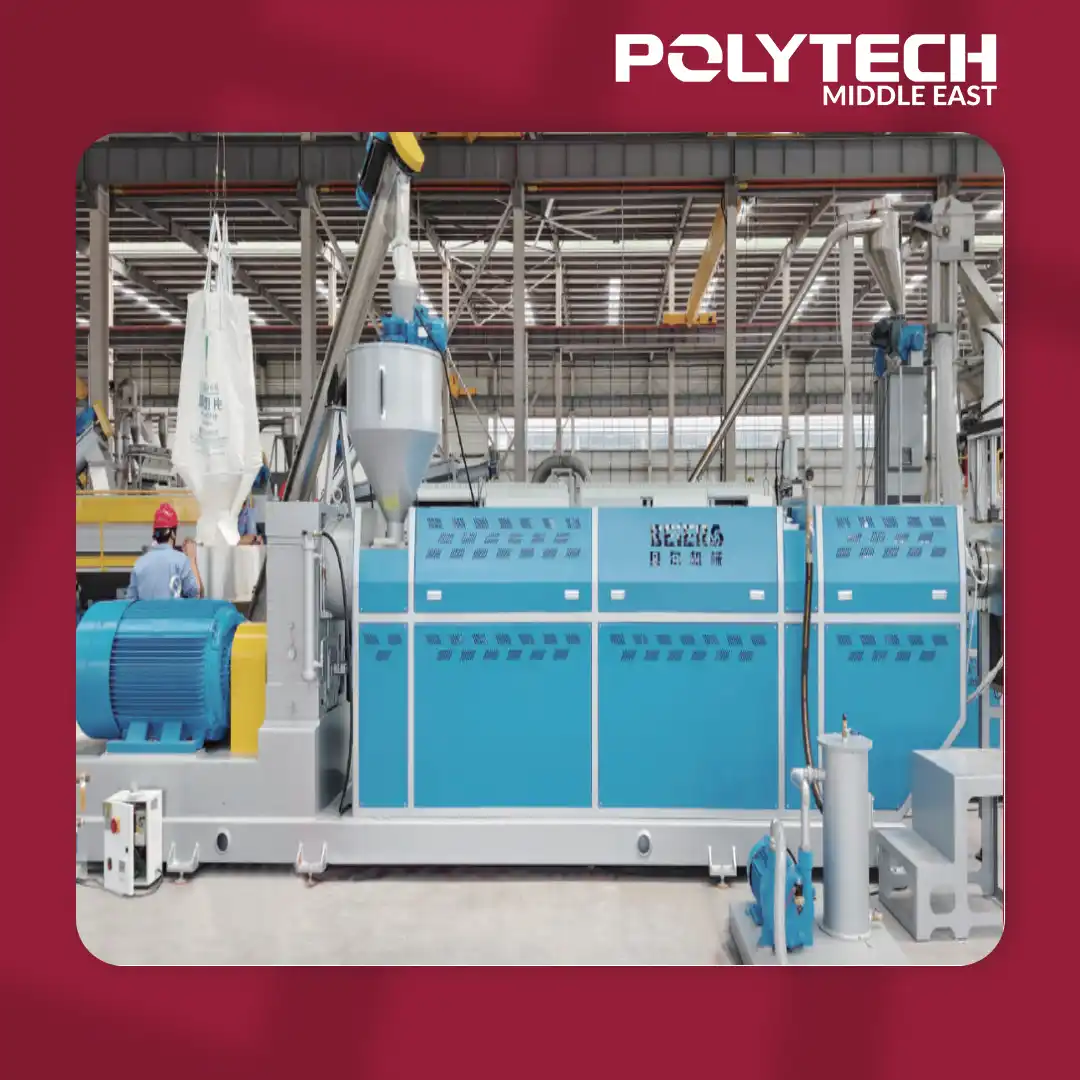

The Plastic Flake Pelletizing Line is a high-efficiency recycling system designed to convert cleaned and sorted plastic flakes into uniform, high-quality pellets. Ideal for PET, HDPE, PP, and mixed plastics, it supports a wide range of downstream applications including injection molding, blow molding, film extrusion, sheet production, thermoforming, and fiber manufacturing. The system combines advanced extrusion technology, automated control, and energy-efficient operation to deliver consistent quality and reliable performance.

Description

Introduction

The Plastic Flake Pelletizing Line is an advanced, high-efficiency recycling system designed to transform cleaned and sorted plastic flakes into premium-quality plastic pellets. As industries worldwide move toward sustainable and environmentally friendly solutions, this line offers a reliable and versatile method for converting post-consumer and post-industrial plastics into reusable raw materials. It is suitable for a wide variety of plastic types, including PET, HDPE, PP, and other mixed polymers, making it ideal for facilities processing diverse plastic waste streams.

This system not only maximizes material recovery but also ensures that the final pellets meet the highest standards for downstream processing applications. Whether the end goal is injection molding, blow molding, film extrusion, sheet production, or thermoforming, the Plastic Flake Pelletizing Line guarantees consistent quality, helping manufacturers reduce waste, energy consumption, and operational costs.

Advanced Technology and Process

The line incorporates cutting-edge extrusion and pelletizing technology to achieve uniform melting and smooth plastic flow. The feeding system is designed to handle flakes of various sizes and contamination levels, ensuring consistent throughput without blockages or interruptions. High-precision pelletizers cut the extruded material into uniformly sized pellets, while integrated cooling and drying units ensure optimal moisture content and surface quality.

The extrusion system can be adjusted for temperature, screw speed, and cutting rate, providing full control over the pellet characteristics. This level of customization ensures that the produced pellets meet specific industrial requirements, offering superior performance in injection molding, extrusion, and other plastic processing applications.

Operational Efficiency and Energy Savings

Designed for high-volume, continuous operation, the line emphasizes efficiency and energy conservation. Automated process control allows operators to monitor and adjust operational parameters in real-time, maintaining optimal performance while reducing material waste and energy consumption. The modular design enables easy maintenance, cleaning, and rapid changeovers, minimizing downtime and increasing overall productivity.

Additionally, the system’s intelligent monitoring reduces the risk of operational errors, providing stable output even under varying material conditions. The combination of automation and modularity ensures that recycling facilities can operate efficiently without sacrificing product quality or reliability.

Safety, Reliability, and Environmental Responsibility

Operator safety and environmental compliance are key priorities in the design of this pelletizing line. The system is equipped with safety sensors, automated shutdown features, and user-friendly control panels to prevent accidents and protect equipment. At the same time, energy-efficient components and emission-reducing processes minimize environmental impact, making this line a sustainable choice for modern recycling operations.

The robust construction and high-quality materials used in the line ensure long-term reliability, while its environmentally responsible design helps facilities meet regulatory standards and corporate sustainability goals.

Key Benefits

- Produces high-quality pellets with uniform size, smooth surface, and low moisture content

- Capable of processing PET, HDPE, PP, and mixed plastic types

- Continuous high-volume operation with optimized energy consumption

- Automated controls for precise and stable processing

- Modular design for easy maintenance and rapid changeovers

- Safe and environmentally responsible operation

- Reduces material waste and operational costs

The Plastic Flake Pelletizing Line combines advanced technology, high operational efficiency, and sustainability to deliver a complete solution for plastic recycling facilities. It provides reliable, consistent, and high-quality output, enabling manufacturers to meet industrial requirements while contributing to a circular economy.

Products

The Plastic Flake Pelletizing Line is widely used across multiple industrial sectors that rely on recycled plastics as raw materials. The high-quality pellets produced by the system make it suitable for a broad range of manufacturing processes, including:

Injection Molding

Used in the production of automotive components, household products, industrial parts, consumer electronics housings, and other molded items that require consistent plastic quality.

Blow Molding

Ideal for manufacturing bottles, containers, tanks, chemical packaging, and other hollow plastic products.

Film Extrusion

Suitable for producing plastic films for packaging, shopping bags, agricultural films, stretch films, shrink wraps, and other thin-film products.

Sheet and Board Production

Used in extrusion lines for producing plastic sheets and boards for advertising panels, construction materials, thermoformed products, and industrial packaging.

Pipe and Profile Extrusion

Commonly applied in the production of water pipes, conduit systems, cable ducts, profiles, window frames, and other extruded structural products.

Thermoforming

Recycled pellets can be used to form trays, cups, lids, food packaging, medical containers, and large industrial thermoformed parts.

Fiber and Textile Manufacturing

PET pellets in particular are widely used for producing polyester fibers, woven and non-woven fabrics, carpeting materials, and textile blends.

Compounding and Masterbatch Production

The pellets can be reprocessed with additives, fillers, colorants, or reinforcement materials to produce customized polymer compounds and masterbatches.

General Recycled Plastic Reprocessing

Ideal for facilities that resell plastic pellets as raw material to other manufacturers across automotive, packaging, home appliances, construction, and consumer goods industries.

Applications

Gallery

Main Features

| Parameter | Specification |

|---|---|

| Model | PFP-1000 / PFP-2000 / PFP-3000 (depending on capacity) |

| Processing Capacity | 500 – 5000 kg/h (depending on material type and line configuration) |

| Applicable Materials | PET, HDPE, PP, Mixed Post-Consumer Plastics |

| Extruder Type | Single-Screw / Twin-Screw (depending on model) |

| Screw Diameter | 65 – 120 mm |

| Motor Power | 15 – 200 kW (depending on extruder size) |

| Pellet Diameter | 2 – 4 mm |

| Cooling Method | Water Cooling / Air Cooling |

| Drying System | Hot Air Dryer / Centrifugal Dryer |

| Control System | PLC with Touchscreen HMI |

| Operating Voltage | 380 V / 50 Hz (customizable) |

| Dimensions (L × W × H) | 15 – 35 m × 2 – 5 m × 2.5 – 4 m (depending on capacity) |

| Weight | 10 – 50 tons (depending on configuration) |

| Energy Consumption | 0.5 – 1.2 kWh/kg (depending on material type and line speed) |

| Noise Level | < 85 dB |

| Optional Features | Automatic Feeding System, Magnetic Separation, Color Sorting, Water Recycling System |

Related products

-

Plastic Recycling Lines

Strand Pelletizing Line

-

Plastic Recycling Lines

500–8000 KG/H PET Bottle Washing Line

-

Plastic Recycling Lines

Agglomeration Pelletizing Line

-

Plastic Recycling Lines

PET Flake Pelletizing Line