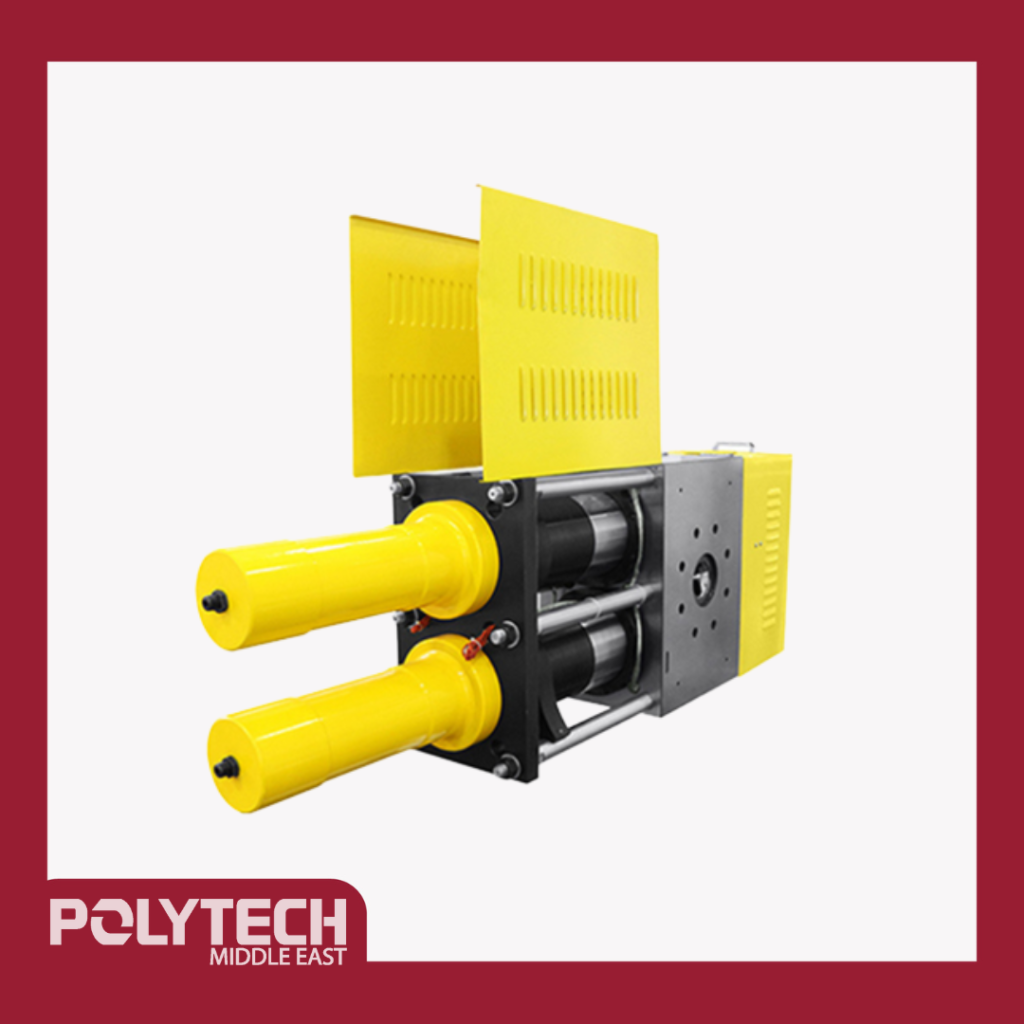

Hydraulic Auto Screen Changer

Screen changer is used for chemical fiber, blown film, flat film, cast film production, pipe, sheet, wire, fiber manufacturing, pelletizing line, recycling, etc.

Applications

Suitable to produce various thermoplastics, mainly for the filtration of material mixtures.

1. Single-column hydraulic screen changer: Equipped with two working screens, it realizes very fast screen changes,

improving production efficiency and maintenance.

2. The filter change time is within 2 seconds. It enjoys a very good sealing effect with the ring and water cooling, the

double sealing system at the top and bottom of its body.

3. The screen design adopts oval-shaped holes to double filter the amount to ensure high output.

4. Equipped with an extremely precise electronically controlled ruler system, it enjoys very smooth and rapidly changing

movements. Hydraulic control system to ensure safe operation.

5. It works well even at high temperature of 300℃ and high pressure of 25MPa-35Mpa.

Description

Specifications

Hydraulic screen changer of double-pillar type

1. changing by hydraulic.

2. Machine non-stopped with screen changing.

3. High wear resistance, high-voltage, high-precision filter design, filter quality and increase the effective area.

4. Automatic adjustment seals, better sealing performance, to meet any high polymer extrusion rate of production can

be extruded with different criteria used in conjunction with machine.

5. Screen design using oval hole doubles the amount of filtering to ensure high output.

6. Easy to operate, using precision guide groove, so that the filter plate accurately installed automatically, without

adjustment position.

Single board screen changer

1. Suitable for all kinds of plastic materials.

2. Quick hydraulic screen changing system.

3. No leakage.

4. High wear resistance and precision.

5. Export to nearly 60 countries.

6. New design, professional screen changer supplier.

Details of the Single board screen changer

1. Rich experience.

2. Strict quality inspection

3. Free operation without leakage

4. Filter alternation is less than 2 seconds

5. No bubbles

6. Short stay time

7. Fully automatic compensation of sealing surface gap, high pressure resistance, high temperature resistance, and no

material leakage. Screens containing large filtration areas are especially suitable for high-yield production lines at high

pressures.

8. No need to change the screen, operation and maintenance, reliable higher output and lower energy consumption, 80%

of the screen caused by the waste material -90% drop, the machine is easy to stop working.

Related products

-

Machines

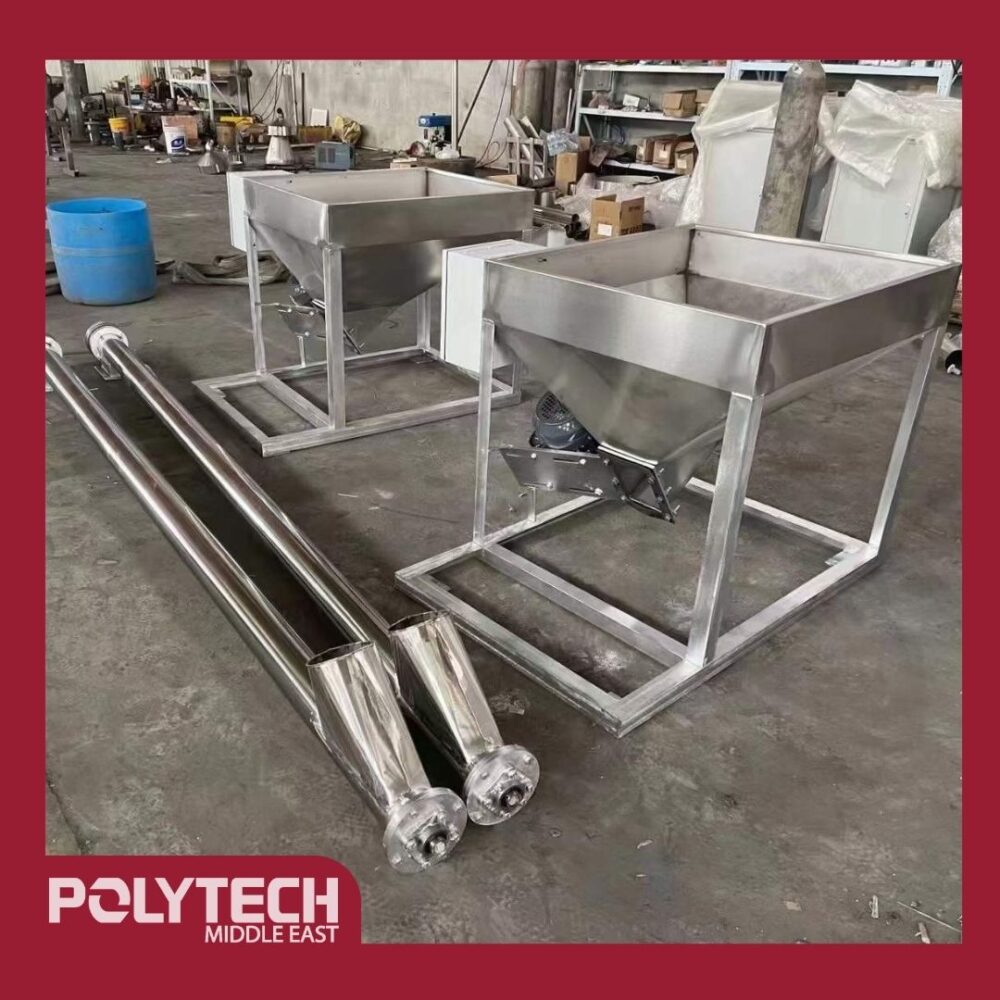

Raw Material Storage Silos

-

Machines

Spiral Feeder

-

Machines

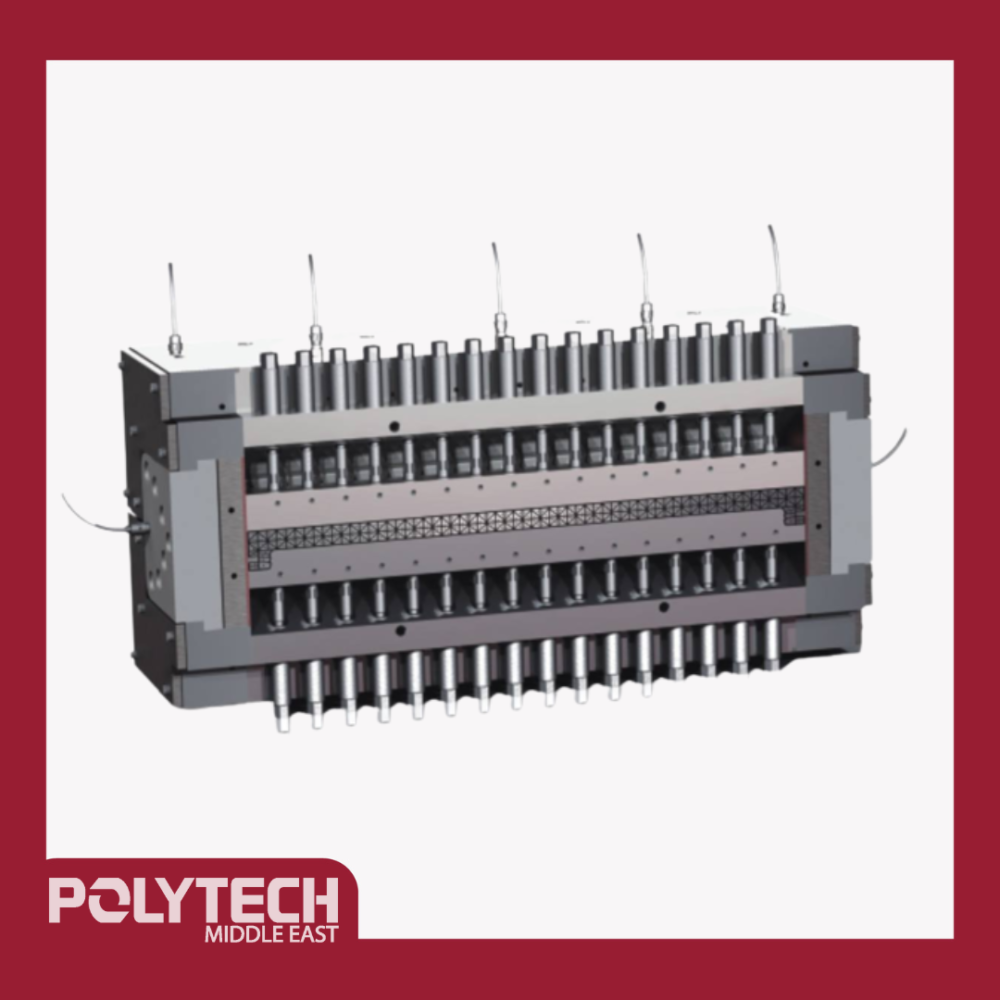

Hollow Profile Dies