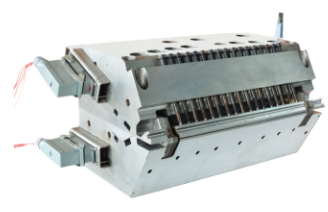

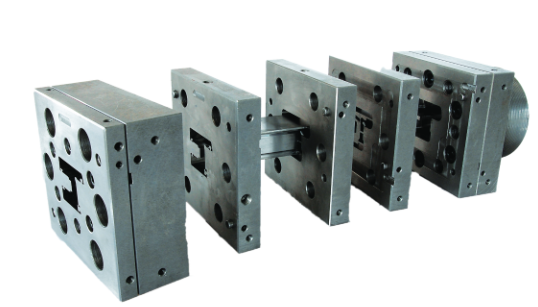

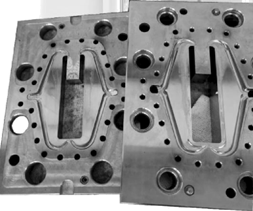

Foaming Profile Tooling

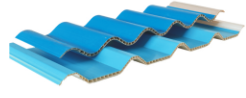

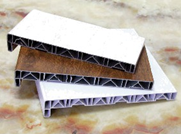

Explore foaming profile tooling for creating lightweight, insulated, and sound-absorbing profiles. Precision solutions for automotive, construction, and packaging industries.

Category -> Extrusion Toolings and Moulds