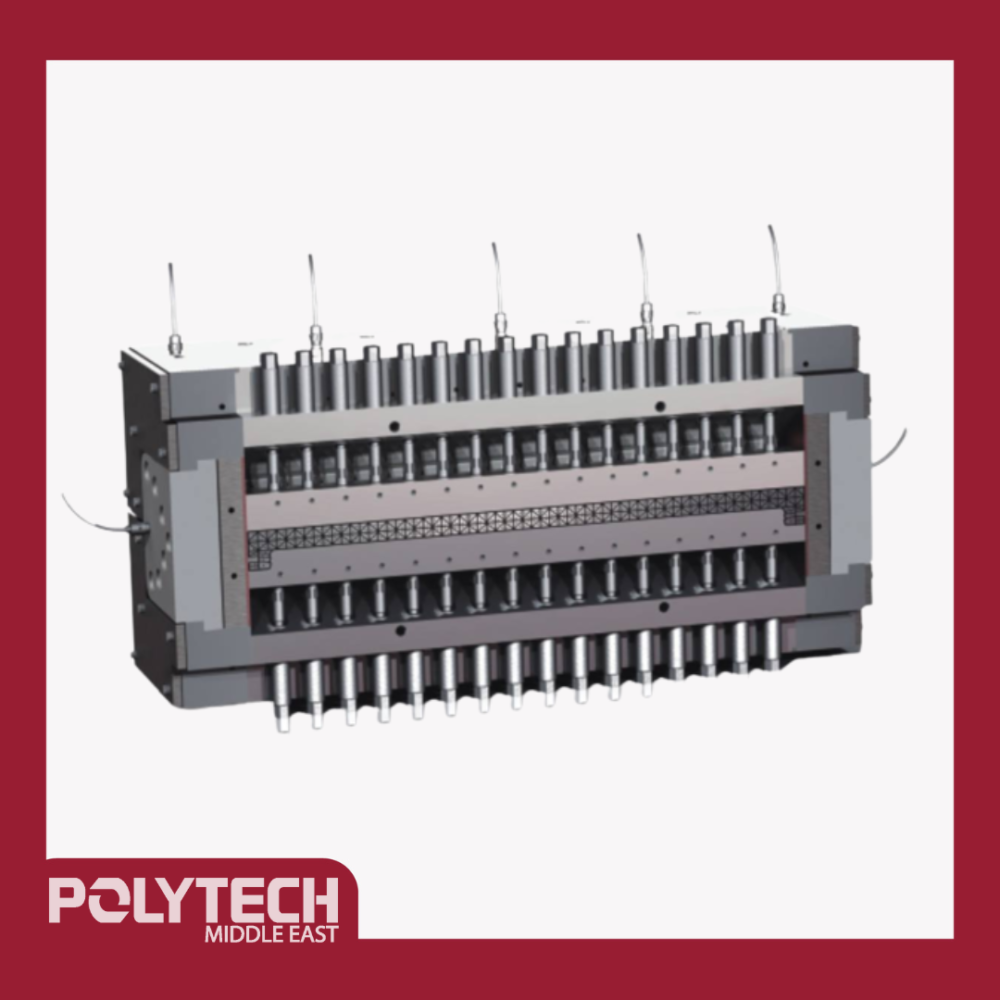

Film Dies

Cast film die series, including CPP/CPE cast film, stretch film, high barrier cast film, etc.

Application

Packaging composite film, vacuum aluminum-plating film, stationery film, cooking film, high-barrier film, stretching film and embossed film.

Widely used in health, medical, construction, electron, battery and automobile industry. The final products include diaper, medical protective article, protective clothing, roof protective material and breathable water-proof material.

Product Parameters

Traditional die width for CPP/CPE film:2000mm,2500mm,3000mm,3500mm,3600mm,4500mm,5000mm,5500mm,6000mm or customized.

Description

Precise Manufacturing

· Advanced European integrated machining center can meet the processing of any inclined and curved surface, one-time forming with spindle 360° rotating. Length error of 5000mm extrusion die is fixed within ±3μm.

· Alloy steel for die production: P20,2714,2311, SUS420/630,5CrNiMo, etc.

· Die surface treatment can be proceeded with nickel alloy, tungsten carbide, hard chrome and Nano diamond alloy.

For chrome- plated thickness, it is from 0.02 to 0.05mm, hardness is HV900-1000.

· For special requirement for high-quality die lip, it can be processed with tungsten carbide with lip closed angle at R0.03mm.

· International highly-ranked instruments such as Vickers hardness tester, chrome-plated thickness gauge, optical non-contact detector provides accurate testing data.

· KUNZ straightness detector is used to verify straightness tolerance of die lip with high precision and efficiency.

For 1000mm standard extrusion die, tolerance is within ±0.02mm;

For 1000mm precise coating die, tolerance is within ±0.002mm.

More than 35,000 extrusion dies have been sold to 8,000 end users directly or indirectly from more than 30 countries and areas.

Automatic Die

· Automatic die can conduct automatic fine-tuning by the thermal expansion bolt when receives accurate feedback from thickness gauge.

· There is heat insulation device installed between thermal expansion bolt and die body, reducing heat conduction.

· The independent air cooling system optimizes the response time, very suitable for production of low-temperature and heat-sensitive material.

· Efficiently and quickly controls product’s absolute preciseness, with tolerance at ±1%.

· Internal or external deckle can be equipped selectively.

Related products

-

Machines

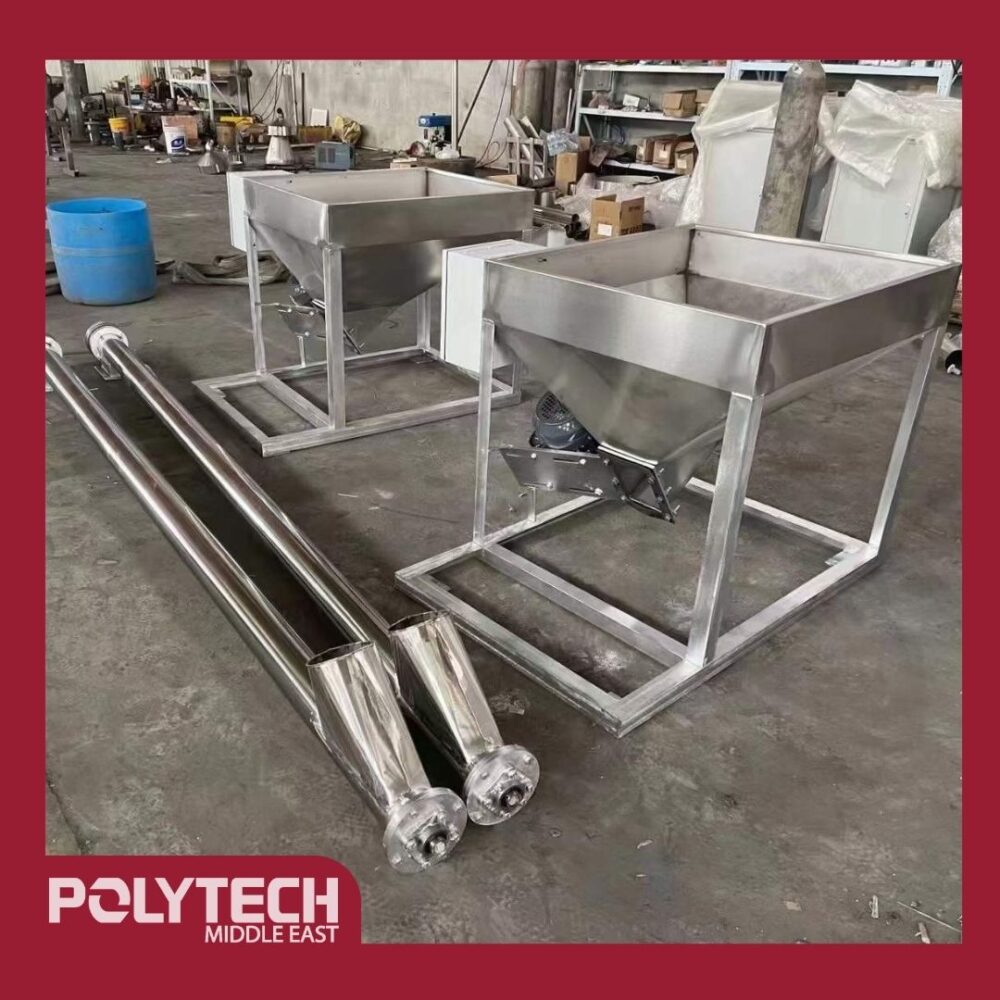

Spiral Feeder

-

Machines

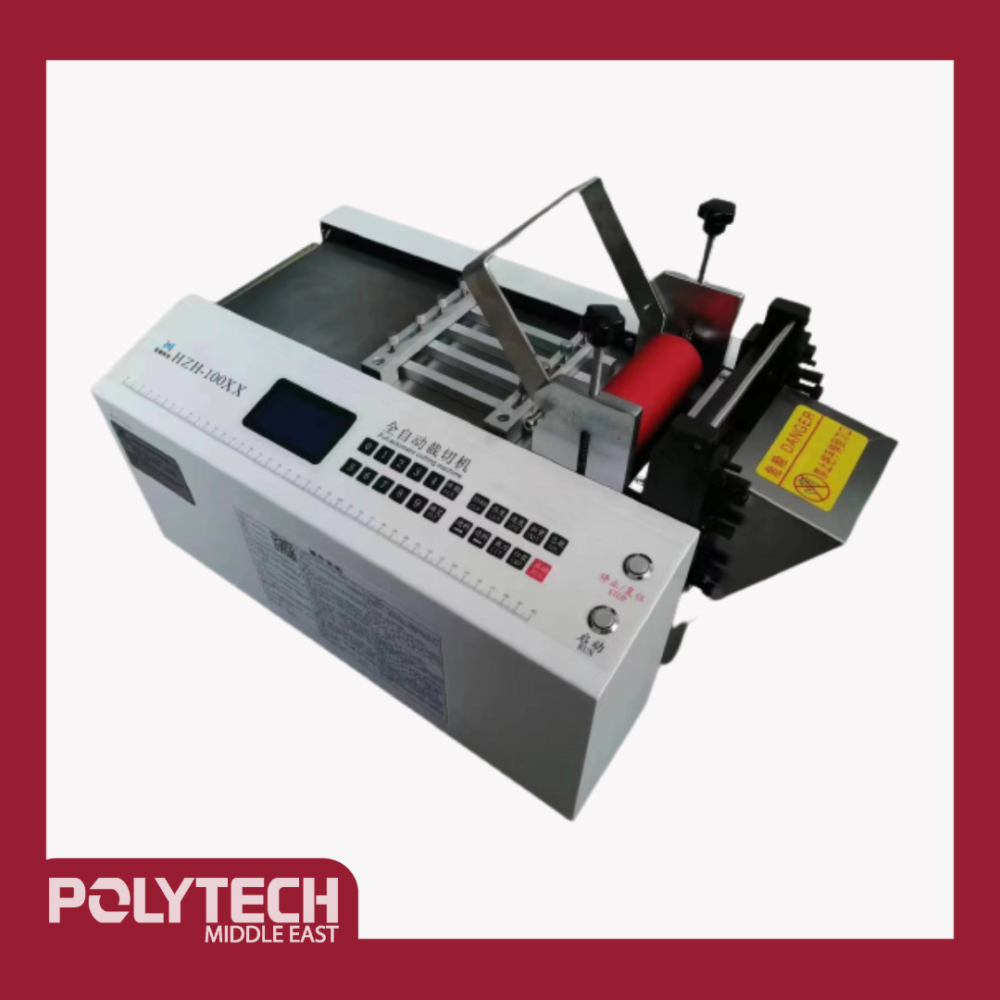

Measuring cutting machine, HZH-100

-

Machines

Hollow Profile Dies