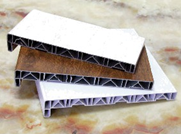

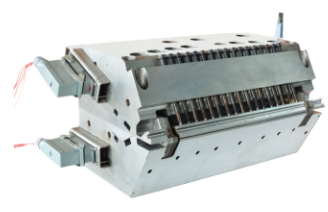

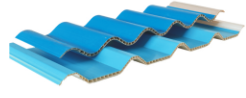

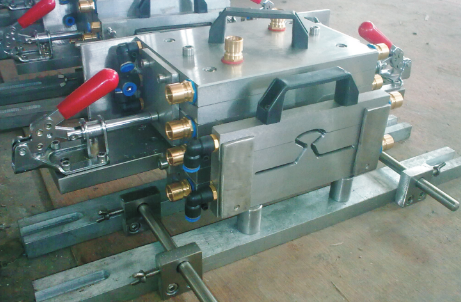

EXTERNAL WALL CLADDING AND CEILING PANEL TOOLING

Discover advanced tooling for manufacturing and installing external wall cladding and ceiling panels. High-precision equipment for wood, metal, plastic, and composite materials.

Category -> Extrusion Toolings and Moulds