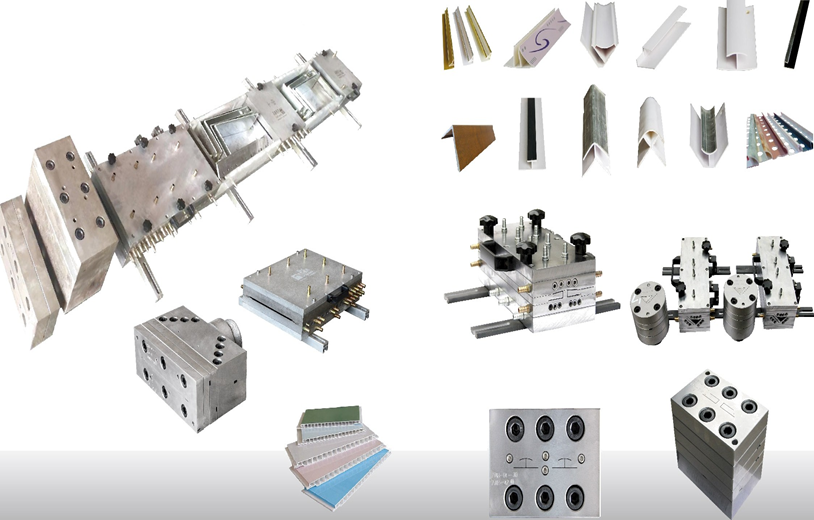

Die Head Mold

Explore die head molds for shaping molten materials into precise profiles. Ideal for pipes, panels, and profiles with consistent quality and customizable designs.

Description

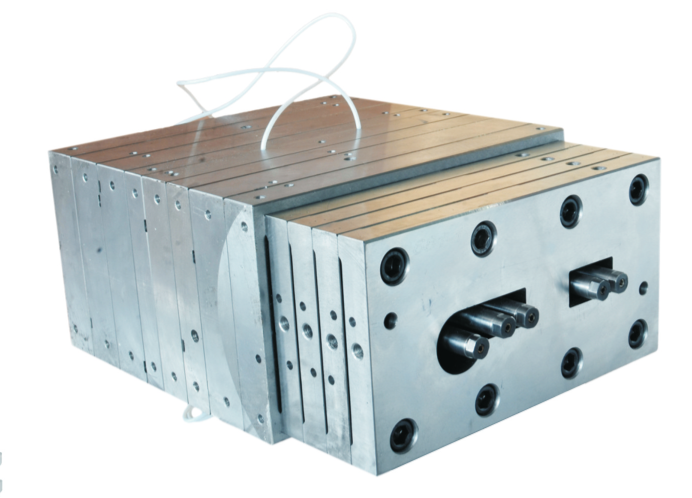

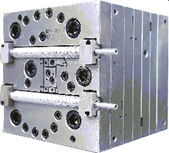

A die head mold is an essential component in the extrusion process, designed to shape molten materials into specific profiles. This tool ensures uniform thickness, smooth surfaces, and precise shapes, making it a cornerstone in the production of products such as pipes, panels, and profiles.

With customizable designs, die head molds cater to a variety of shapes and sizes, ensuring consistent quality and efficient production. Industries like construction and packaging rely heavily on these molds for their precision and reliability.

Type

The mold channel within the die head shapes materials such as PVC and WPC into specific profiles during the extrusion process. By maintaining uniform flow, it creates consistent shapes like grooves or U-channels with smooth surfaces and stable thickness. This makes it ideal for applications such as:

- Cable Trays

- Drainage Systems

- Panel Framing

Components of the Molding Process

- Printing: Adds designs or markings to the extruded product, often using UV or digital printing technologies.

- Whole Mandrel: Ensures stable material flow, enhancing uniformity and reducing the risk of defects in the final product.

- Guide Pole: Keeps the extruded material properly aligned, preventing it from falling or shifting during the process.

- All Corve: Manages proper curvature, flow, and alignment of the material, shaping and guiding it to achieve the desired profile with precision.

Benefits of Die Head Mold

- Enhanced Precision: Ensures uniform thickness and smooth surfaces.

- Customizable Designs: Adapts to various shapes and sizes.

- Improved Efficiency: Streamlines production and minimizes material waste.

- Versatility: Suitable for a wide range of applications and industries.

Applications

- Construction: Producing structural profiles, drainage systems, and panel frames.

- Packaging: Creating customized panels and profiles for packaging solutions.

- Industrial Use: Manufacturing components for cable trays and other specialized applications.

Related products

-

Extrusion toolings and moulds

Calibrator

-

Extrusion toolings and moulds

Window Sill Plate Mold

-

Extrusion toolings and moulds

Ceiling Panel and Clip Mold

-

Extrusion toolings and moulds

WPC Tooling