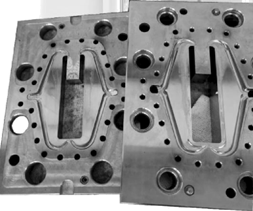

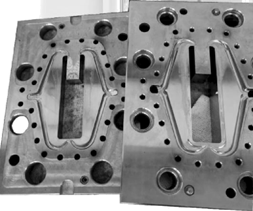

CO-EXTRUSION TOOLING

Explore CO-extrusion tooling for precision-engineered, multi-layered profiles. Versatile and efficient solutions for automotive, packaging.

Category -> Extrusion Toolings and Moulds

Explore CO-extrusion tooling for precision-engineered, multi-layered profiles. Versatile and efficient solutions for automotive, packaging.

CO extrusion tooling utilizes specialized dies to extrude multiple materials simultaneously into a single product. This advanced manufacturing process enables the creation of complex profiles with varying layers, each offering unique properties. Widely used in industries such as automotive and packaging, CO extrusion tooling delivers products with enhanced performance, aesthetics, and functionality.

CO extrusion tooling supports a variety of industries and products, including:

Types:

Custom dies designed to accommodate specific product requirements, such as thickness, material compatibility, and profile complexity.