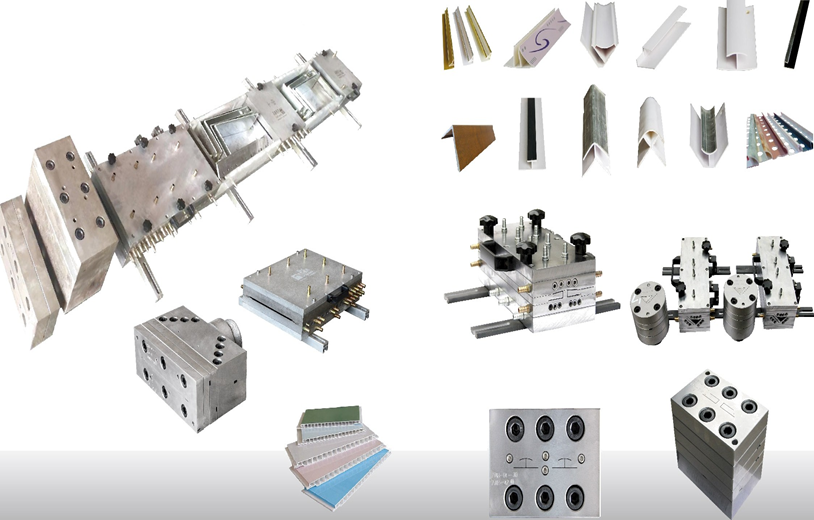

Building Material Tooling

Discover building material tooling for shaping, cutting, and assembling construction materials. Precision and efficiency tools for woodworking, masonry, metalworking, and more.

Description

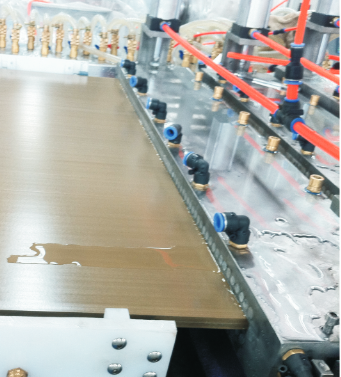

Building material tooling refers to a broad spectrum of machinery and equipment designed for shaping, cutting, assembling, and finishing construction materials. These tools range from basic hand tools to advanced automated systems, each tailored for specific tasks in construction, such as woodworking, metalworking, concrete work, and masonry. Essential for modern construction, these tools ensure precision, efficiency, and quality in building processes, supporting projects from simple carpentry to large-scale industrial manufacturing.

Features and Applications of Building Material Tooling

Key Features

- Precision: Delivers accurate shaping and finishing for high-quality outcomes.

- Efficiency: Optimizes construction speed and reduces material waste.

- Durability: Designed to withstand heavy-duty construction use.

- Versatility: Applicable across various construction materials and techniques.

- Automation: Advanced tools like CNC machines and robotic systems enhance productivity and consistency.

Applications

Building material tooling is indispensable in:

- Woodworking: Cutting, shaping, and assembling wooden components for furniture, flooring, and structures.

- Masonry and Concrete Work: Mixing, shaping, and finishing concrete and stone materials.

- Metalworking: Fabricating metal structures, beams, and panels for construction.

- Plumbing and Electrical Work: Precision tools for pipe fitting and electrical installations.

- Painting and Finishing: Surface preparation and coating applications for aesthetic and protective purposes.

Types of Building Material Tooling

Hand Tools

Hammers, screwdrivers, chisels, and other manual tools for basic construction tasks.

Power Tools

Drills, saws, grinders, and nail guns for efficient material processing and assembly.

Machine Tools

CNC machines, lathes, and presses for precise and automated material fabrication.

Robotic Systems

Automated arms and assembly lines for large-scale industrial construction projects.

Benefits of Building Material Tooling

- Enhanced Quality: Ensures consistent dimensions and finishes for materials.

- Increased Productivity: Speeds up construction timelines with automated processes.

- Cost Savings: Reduces material wastage and labor costs.

- Safety and Sustainability: Promotes safe operations and eco-friendly construction practices.

Tooling Process Overview

- Material Selection: Identifying suitable tools for specific materials and construction tasks.

- Cutting and Shaping: Using precise tools for dimensioning and profiling.

- Assembly and Joining: Fastening components securely using hand or power tools.

- Finishing and Coating: Ensuring smooth surfaces and applying protective layers.

- Quality Assurance: Verifying that materials and structures meet project specifications.

Related products

-

Extrusion toolings and moulds

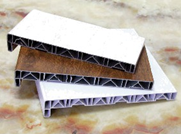

Ceiling Panel and Clip Mold

-

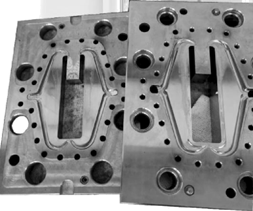

Extrusion toolings and moulds

Window Sill Plate Mold

-

Extrusion toolings and moulds

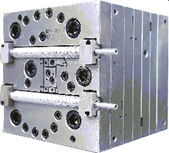

Die Head Mold

-

Extrusion toolings and moulds

CO-EXTRUSION TOOLING