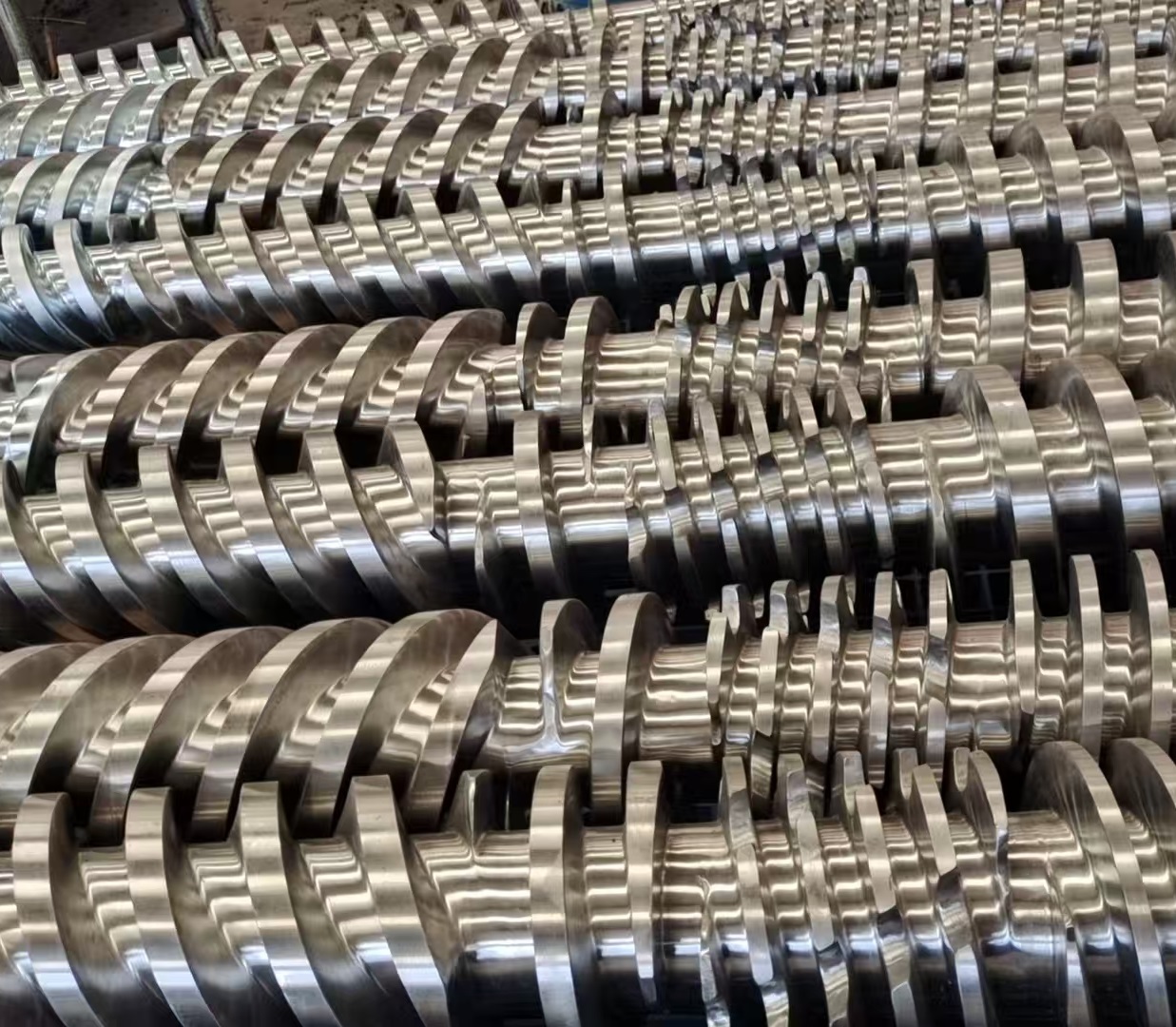

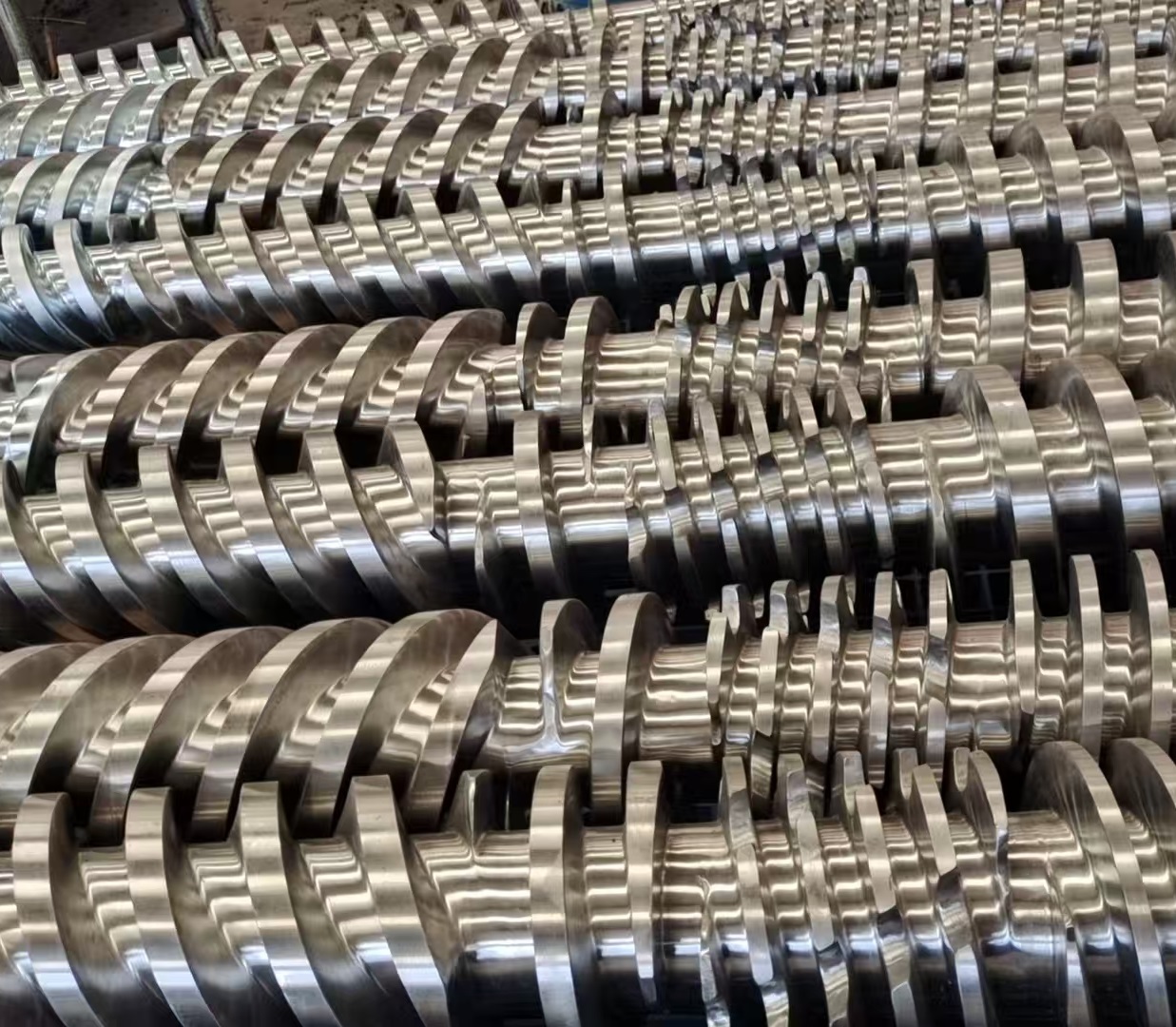

55/120 Conical Twin Screw Barrel

Enhance your PVC extrusion process with the 55/120 conical twin screw barrel. Available for fast delivery, superior performance, and cost efficiency.

Category -> Machines and Spare Parts

Enhance your PVC extrusion process with the 55/120 conical twin screw barrel. Available for fast delivery, superior performance, and cost efficiency.

Efficiency and reliability are key to high-quality PVC extrusion. Our 55/120 conical twin screw barrel, available directly from our Turkey warehouse stock, delivers outstanding performance and advanced features for rigid PVC processing. By sourcing locally, you save time and costs while benefiting from a trusted partner committed to supporting your success.

Counter-rotating conical design improves pressure distribution and conveying efficiency. The double cone configuration with tapered screws ensures gradual pitch changes for optimized material flow.

Enhanced plasticization and compression provide a high compression ratio, ensuring thorough plasticization and uniformity. Superior mixing and shearing make it ideal for rigid PVC processing.

Advanced barrel composition features intersecting conical holes and an exhaust groove for efficient vapor discharge. The modular design reduces replacement costs and downtime.

Precision manufacturing is achieved through high-precision CNC screw milling machines. Variable pitch and depth technology enhance extrusion performance and product consistency.

We offer the flexibility to supply the screw and barrel separately or as a complete set, depending on your specific needs.

Local availability ensures faster delivery and lower costs by avoiding lengthy import processes.

Trust and reliability are at the core of our business, providing high-quality products backed by industry expertise.

Comprehensive support includes technical guidance and after-sales service to ensure smooth operations and maximum productivity.

PVC pipe and profile manufacturing requires high precision and consistency for accurate shaping.

WPC (wood plastic composite) extrusion benefits from enhanced mixing and material compatibility.

CPVC and UPVC processing is optimized with high-performance screw and barrel designs, ensuring durability and efficiency.

Size: 55/120

Motor Power (kW): 22

Screw Rotation Speed (RPM): 34.7

Output Capacity (kg/h): 120-140

Material: High-strength 38CrMoAlA for exceptional durability

Processing Method: Nitriding and bimetallic for enhanced wear and corrosion resistance

Nitrided Hardness: HV960-HV1100 ensures a long operational lifespan

Nitrided Case Depth: 0.45mm-0.8mm

Surface Roughness: Ra 0.4 for seamless material flow

Screw Straightness: R0.015mm for precision alignment

Bimetallic Alloy Layer: 2mm-2.5mm for extra protection against abrasion

Length-to-Diameter Ratio: 1: (15-45), optimized for efficient extrusion