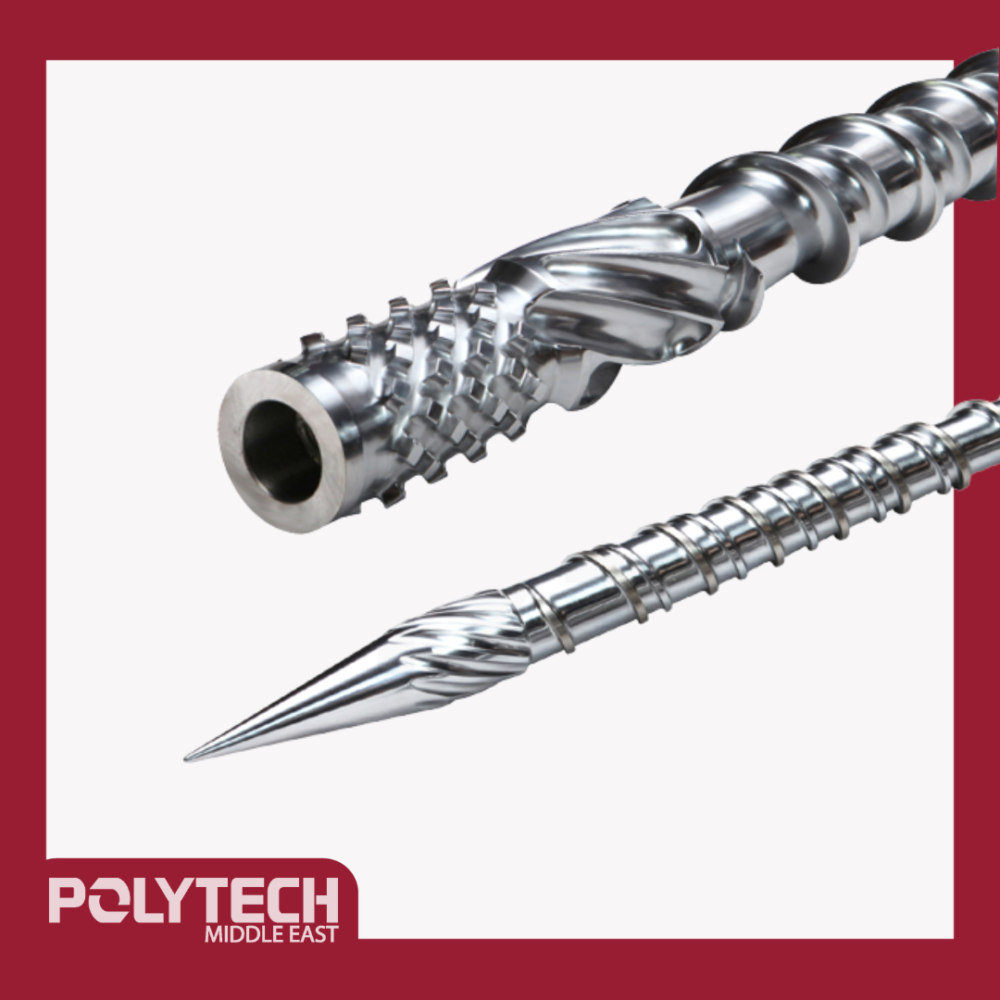

51 / 105 65 / 132 80 / 156 PVC Conical DOUBLE Twin Screw Barrel For Plastic Extruder

Conical twin-screw extruder is an efficient mixing and extrusion equipment. The machine has the characteristics of low shear rate, difficult material decomposition, uniform plasticizing and mixing, stable quality, high output, wide application range and long service life.

Description

Using machining center finishing, reasonable processing technology, advanced testing equipment, to ensure that the processing accuracy of each product.

Twin-screw extruder screw element:

– convenient interchangeability by agile combination.

– fulfill efficient self-cleaning, transmission, compounding, pressure-forming and etc.

– made of high speed tool steel W6Mo5Cr4V2, or anti-corrosion steel 38CrMoAlA by speed treatment.

The flexible modular principle is realized with screw barrel sections from the wide range of different designs possible. Fast, intensive and uniform heating of the screw barrel section is ensured by electrical heaters. The barrel sections are cooled with water by means of an internal bore system with bores arranged close to the inside barrel wall.

Conical twin-screw extruder is an efficient mixing and extrusion equipment. The machine has the characteristics of low shear rate, difficult material decomposition, uniform plasticizing and mixing, stable quality, high output, wide application range and long service life.

Product name Conical Twin Screw Extruder

Other name Conical twin extruder

Application Plasticizing PVC or wood-plastic products

Features stable quality, high output, wide application range

Drive Motor

For the molding of rigid PVC products such as PVC profiles/pipes, conical twin-screw extruders have outstanding advantages and are also mainstream processing models. Under the same screw flight structure, although the length of the feeding section of the parallel twin-screw is 60% longer than that of the conical twin-screw, the heat transfer area is 45% smaller. The shear heat generated by the screw, that is, the conical screw is greater than that of the parallel screw, so the plasticizing effect of the conical twin screw on the material in the feeding section is better than that of the parallel screw.

In addition, because the volume of the conical twin-screw decreases continuously during the conveying process, the extrusion effect is enhanced, so that the material can fully contact the screw, so that the conical screw can provide higher energy conversion, so that the pre-plastic effect can be improved. better. In the metering section, the conical twin-screw has a smaller screw diameter, which weakens the shearing effect on the material and generates less shear heat, which just meets the requirements of PVC plasticizing extrusion.

1. Parallel twin-screw barrel series:

φ50/2 (2 represents twin screw), φ65/2, φ80/2, φ90/2, φ105/2, φ125/2, φ130/2, φ150/2, φ180/2, φ200/2

2. Conical twin-screw barrel series

sjs 35 (φ35/80-2), sjs 51 (φ51/105-2), sjs 55 (φ55/113-2), sjs 65 (φ65/132-2), sjs 80 (φ80/156-2), sjs 92 (φ92/188)

Screw steering: different directions outward

Screw speed:

1-40,1-32,1-36,1-32,1-32,1-32

Effective length of the screw (the effective length of the screw generally refers to the length of the screw part):

810mm, 1070mm, 1200mm, 1441mm, 1800mm, 2500mm

3. Extrusion and injection molding single screw, barrel series

Specifications: diameter φ15mm-diameter φ360mm

Aspect ratio (the effective length of the screw divided by the diameter of the screw): l/d=15-45

4. Rubber screw and barrel series

4.1 Pin screw, barrel

Specifications: diameter φ75mm-diameter φ200mm

4.2 Cold and hot feeding screw, barrel

Specifications: diameter φ30mm-diameter φ250mm

Related products

-

Spare Parts

Single screw extrusion machine

-

Spare Parts

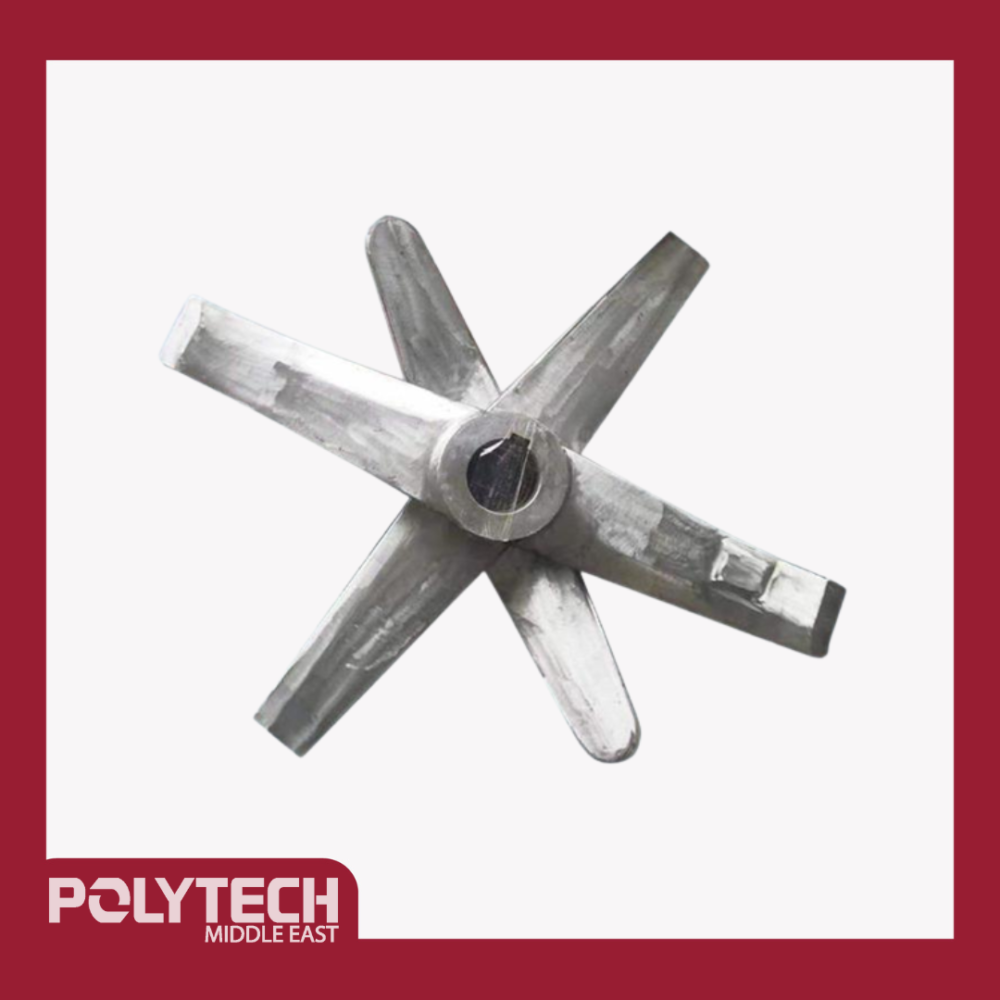

PVC Mixer Blades

-

Spare Parts

Heating Coils

-

Spare Parts

Conical Twin Screws and Barrel