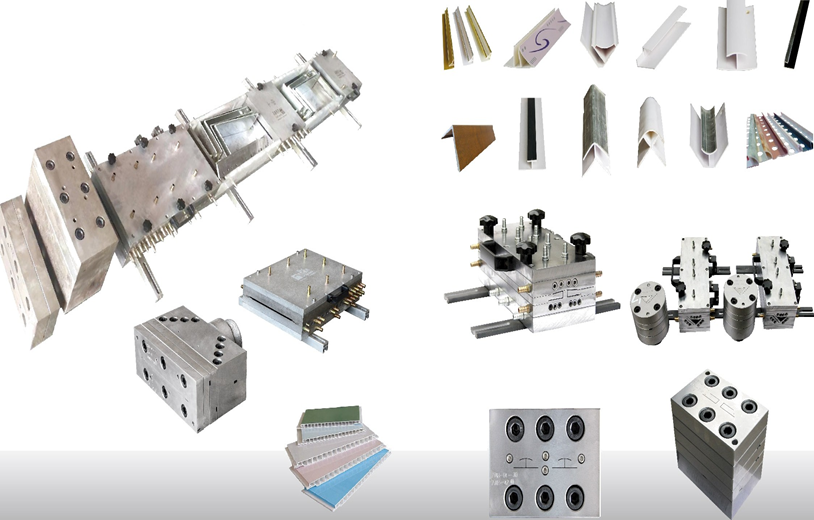

PVC Hollow Board Mold

Discover PVC hollow board molds for producing lightweight, durable boards. Ideal for construction, signage, and interior design with high-quality finishes.

Category -> Extrusion toolings and moulds

Description

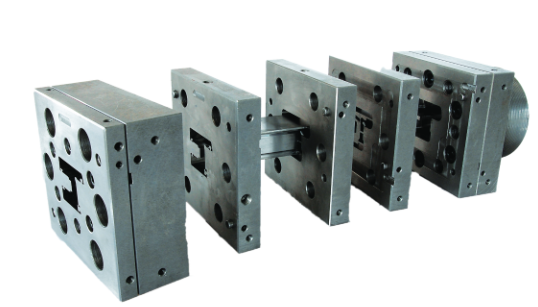

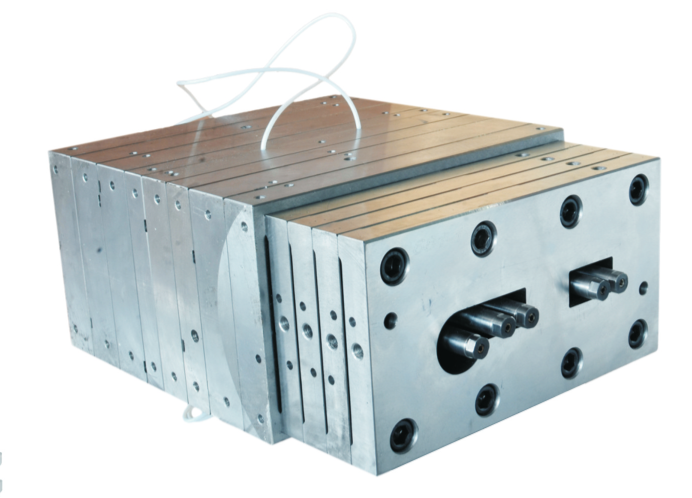

PVC hollow board mold is specialized tool designed to produce lightweight, durable boards with a hollow structure. These molds ensure precise control over board size and thickness, delivering high-quality results while preventing blockages and reducing deformation.

Widely used in construction, signage, and interior design, PVC hollow boards are valued for their durability, moisture resistance, and smooth finishes, making these molds an essential part of reliable and cost-effective board production.

Main Materials

- PVC + Calcium Powder

Product Capacity

- Approximately 1.5 meters to 2 meters per minute

PVC Hollow Board Mold Features and Main Uses

Key Features

- Durability: Produces boards resistant to moisture and wear.

- Precise Control: Ensures consistent thickness and smooth finishes.

- Optimized Material Flow: Prevents blockages and extends mold service life.

- Deformation Prevention: Maintains board integrity and shape during production.

Main Uses

PVC hollow boards are versatile and commonly used in:

- Construction: Wall panels, partition walls, and roofing.

- Signage: Advertising panels with smooth surfaces for printing.

- Packaging: Lightweight and durable packaging solutions.

- Interior Design: Decorative and functional wall applications.

Benefits of PVC Hollow Board Mold

- High Efficiency: Supports fast production rates of up to 2 meters per minute.

- Cost-Effective: Reduces material waste and ensures long-lasting performance.

- Versatile Applications: Adapts to various industries and design requirements.

- Enhanced Quality: Produces smooth, high-quality boards with consistent dimensions.

Related products

-

Extrusion toolings and moulds

Ceiling Panel and Clip Mold

-

Extrusion toolings and moulds

Profile Tooling

-

Extrusion toolings and moulds

Pipe Tooling

-

Extrusion toolings and moulds

WPC Tooling