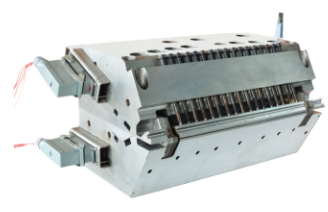

Panel Sheet Tooling

Explore panel sheet tooling solutions for shaping sheet metal into intricate components. Ideal for automotive, construction, aerospace, and electronics industries.

Description

Panel sheet tooling refers to the use of specialized equipment to shape and form sheet metal into precise components. This process employs presses, punches, dies, and bending machinery to produce a wide range of products, including automotive body panels, appliance casings, and structural components. Designed for accuracy and efficiency, these tools ensure that the final products meet stringent quality standards and exact specifications.

Features and Applications of Panel Sheet Tooling

Key Features

- Precision: Ensures accurate shaping and forming of intricate designs.

- Durability: Built to handle high-pressure operations and extended usage.

- Adaptability: Compatible with a variety of metals and customizable for specific product requirements.

Applications

Panel sheet tooling supports diverse industries, enabling the production of:

- Automotive Components: Body panels, doors, and chassis parts.

- Appliance Manufacturing: Casings for refrigerators, ovens, and washing machines.

- Construction Materials: Structural panels, roofing sheets, and building facades.

- Aerospace Parts: Lightweight structural components and enclosures.

- Electronics Industry: Casings for devices and equipment enclosures.

Types of Panel Sheet Tooling

Presses and Punches

High-precision presses and punches for cutting and forming sheet metal with intricate designs.

Dies and Molds

Specialized dies for shaping sheet metal into specific profiles and components.

Bending Equipment

Tools designed to bend metal sheets into desired angles and shapes with precision.

Stamping Machines

Automated systems for large-scale production of metal panels and parts.

Benefits of Panel Sheet Tooling

- High Efficiency: Speeds up production processes while maintaining accuracy.

- Customizability: Allows for tailored solutions to meet specific industry needs.

- Cost-Effectiveness: Reduces material waste and operational downtime.

- Enhanced Quality: Guarantees consistency in product dimensions and strength.

Process Overview

- Design and Customization: Developing dies and tools tailored to product specifications.

- Material Preparation: Preparing sheet metal for processing.

- Cutting and Shaping: Utilizing presses, punches, and dies for desired forms.

- Bending and Finishing: Creating specific angles and applying finishing touches.

- Quality Control: Ensuring each component meets industry standards.

Related products

-

Uncategorized

PC Solid Sheet Extrusion Line

-

Uncategorized

Foaming Profile Tooling