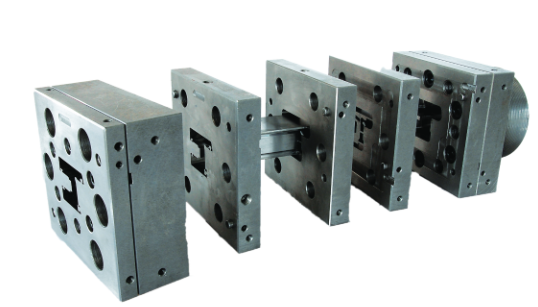

Profile Tooling

Explore versatile profile tooling for shaping metals and plastics into precise profiles. Learn about European, American, and multiple strand tooling for diverse manufacturing needs.

Description

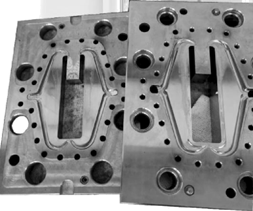

Profile tooling refers to specialized dies and molds designed to shape and extrude materials—primarily metals and plastics—into specific profiles or cross-sectional geometries. These tools are indispensable in manufacturing, enabling the production of components with precise dimensions and intricate designs. Profile tooling ensures efficiency, consistency, and quality, supporting industries ranging from construction to automotive.

Features and Applications

Key Features

- Precision: Ensures exact dimensions and complex geometries.

- Durability: Built to endure high-pressure and high-temperature environments.

- Adaptability: Accommodates various materials and industry requirements.

Applications

Profile tooling finds use across diverse sectors, enabling the production of:

- Construction Components: Structural beams, window frames, railings.

- Automotive Parts: Door frames, trims, and other structural components.

- Industrial Goods: Channels, brackets, and specialized profiles.

- Consumer Products: Furniture components, shelving supports, and decorative trims.

Types

European Profile Tooling

European profile tooling refers to tools designed to meet stringent European standards and regulations. Commonly used in woodworking and manufacturing, this tooling ensures:

- Consistency: Adherence to uniform European design specifications.

- Safety: Compliance with safety protocols.

- Quality: High precision and reliability for various applications.

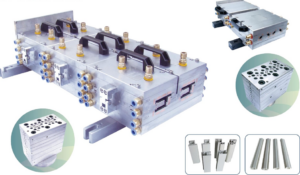

American Profile Tooling

American profile tooling focuses on versatility and productivity, catering to the specific needs of the American market. Key attributes include:

- Flexibility: Custom designs tailored for industry-specific requirements.

- Efficiency: Optimized for high-speed production.

- Durability: Long-lasting tools designed for demanding manufacturing

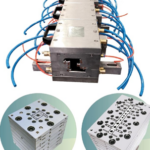

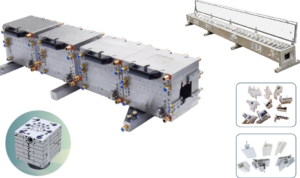

Multiple Strands Tooling

Multiple strands tooling is a specialized extrusion technology used to create profiles with multiple, parallel strands or co-extrusions. This type of tooling allows for:

- Complex Profiles: Combining different materials or colors.

- Applications in WPC Manufacturing: Commonly used for decking, fencing, and cladding.

Customization: Creating unique products with intricate designs..

Benefits

- Enhanced Productivity: Enables high-volume, efficient manufacturing.

- Customizable Outputs: Tailored to meet specific application needs.

- Cost Efficiency: Reduces waste through precision engineering.

- Versatility: Supports a wide range of materials and applications.

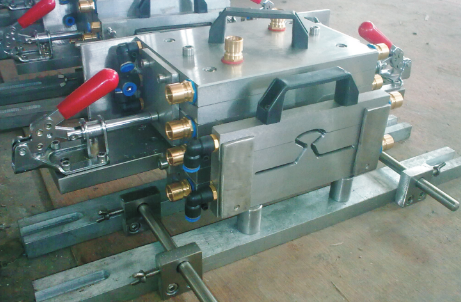

Process

The process typically involves:

- Design and Development: Creating customized dies and molds.

- Material Preparation: Feeding raw materials like metals or plastics.

- Shaping and Extrusion: Forming the material into desired profiles.

- Finishing and Quality Control: Ensuring surface quality and dimensional accuracy.

Related products

-

Extrusion toolings and moulds

PVC Hollow Board Mold

-

Extrusion toolings and moulds

Pipe Tooling

-

Extrusion toolings and moulds

EXTERNAL WALL CLADDING AND CEILING PANEL TOOLING

-

Extrusion toolings and moulds

CO-EXTRUSION TOOLING