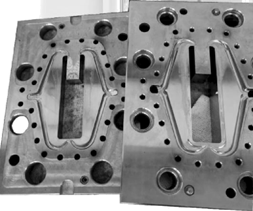

WPC Tooling

Explore cutting-edge WPC Tooling for producing durable and versatile wood-plastic composites. Precision equipment for decking, cladding, furniture, and automotive components.

Description

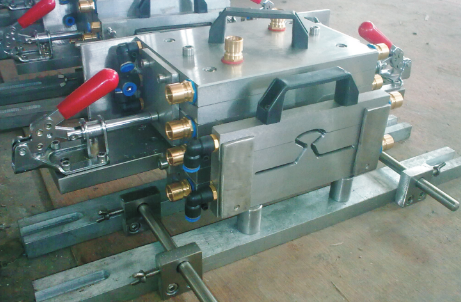

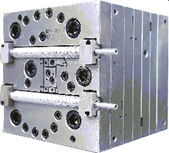

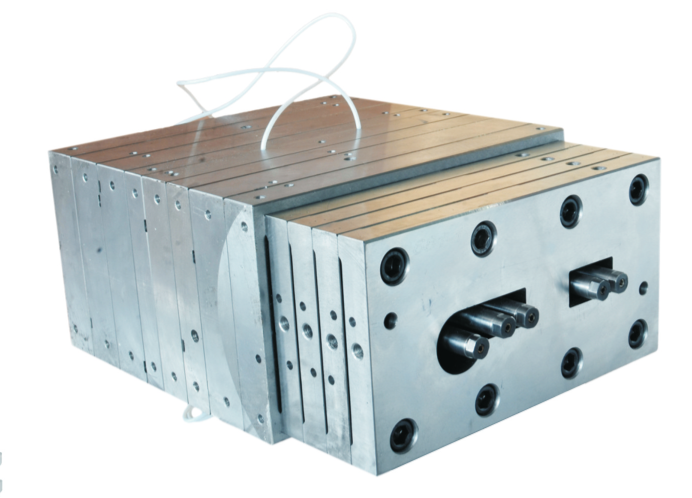

WPC Tooling refers to specialized machinery designed for the production of Wood-Plastic Composites (WPC). This innovative technology combines wood fibers with plastic polymers, resulting in durable, versatile materials suitable for a variety of applications. WPC tooling includes extruders, dies, cutters, and finishing equipment, all essential for shaping, molding, and refining WPC products into their final forms with high precision and consistency.

Features and Applications

Versatile Applications

WPC tooling enables the production of a wide array of WPC products, including:

- Outdoor Applications: Decking, fencing, cladding, railings.

- Indoor Applications: Furniture, cabinets, wall panels, flooring.

- Automotive Components: Dashboards, door panels, trims.

- Packaging Materials: Crates, pallets, storage boxes.

These products demonstrate WPC’s adaptability across construction, interior design, automotive, and logistics sectors.

Key Features

- Durability: Engineered to withstand rigorous industrial use.

- Precision: Ensures consistent quality in WPC product dimensions and aesthetics.

- Adaptability: Compatible with various WPC formulations and applications.

- Efficiency: Optimized for high-speed production and minimal waste.

Process Overview

The WPC manufacturing process, powered by specialized tooling, involves several critical stages:

- Blending: Mixing wood fibers and plastic polymers.

- Extrusion: Using precision extruders and dies to shape the WPC material.

- Cooling and Solidifying: Ensuring the material retains its desired structure.

- Cutting and Finishing: Trimming and refining products for final use.

This seamless process results in high-quality, eco-friendly WPC products with a balance of strength, aesthetics, and sustainability.

Selecting the Right WPC Tooling

When choosing, consider factors like:

- Material compatibility: Wood-plastic ratio and polymer type.

- Production speed and efficiency: Meeting high-demand manufacturing goals.

- Customization options: For specific product dimensions and shapes.

- Maintenance requirements: Ensuring long-term reliability and cost-effectiveness.

Investing in the right tooling guarantees superior product quality, operational efficiency, and a competitive edge in the WPC industry.

Related products

-

Extrusion toolings and moulds

CO-EXTRUSION TOOLING

-

Extrusion toolings and moulds

Calibrator

-

Extrusion toolings and moulds

EXTERNAL WALL CLADDING AND CEILING PANEL TOOLING

-

Extrusion toolings and moulds

Die Head Mold