Product parameters

Product category: corotating bon-screw & barrel,

counter-rotating parallel twin-screw & barrel

Surface processing technology: nitriding, alloy spraying,

chrome plating, etc.

Nitriding hardness HV: 860-980

Straightness: 0.05mm

Surface finish Ra :Ra≤0.2

Applications

It is suitable for extrusion of PVC pipes, profiles and sheet foam products.

It is suitable for extrusion of PE, PP bellows.

Composition and process

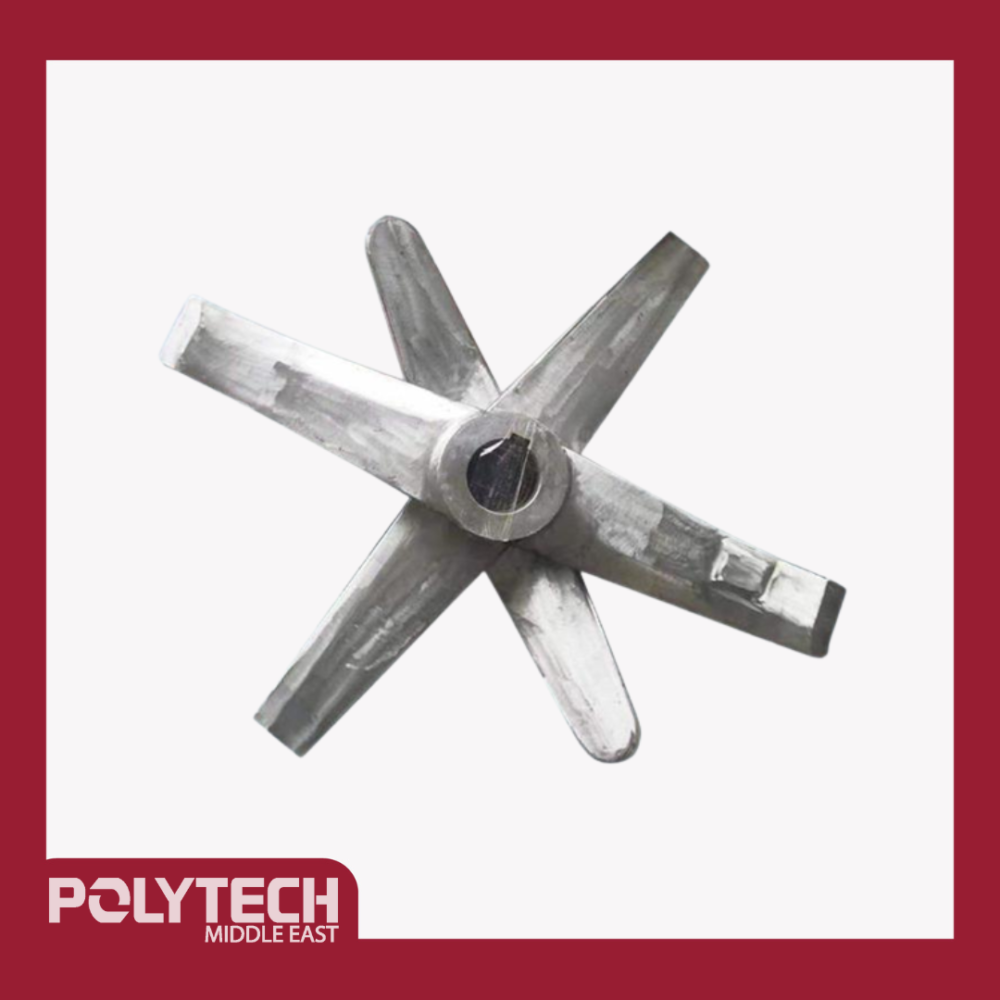

Screw

Screw is made of high-quality 38CrMoALA or 1.8550 forging material, with quenching and tempering to HV290-320, flight surface made with nickel alloy plasma welding, alloy thickness≥1.7mm, hardness: HRC58, nitriding by NITREX process after finishing machine, nitriding depth: 0.5-0.7mm, hardness: HV860-980, grade 2 metallographic structure or above.

Barrel

The barrel is designed as “detachable”, 42CrMo barrel is quenched and tempered to hardness HB290-320, inlaid with German HPT1 alloy sleeve. The thickness of the alloy is more than 7 mm, the hardness is HRC58-62, the shell of the barrel can be used, and the inner alloy sleeve can be replaced after wear out.

Reviews

There are no reviews yet.